We help industry integrate real-time physical chemical analysis solutions to optimize process and quality control.

EQUIPMENT FOR REAL-TIME QUALITY CONTROL

Under the Visum® brand, we manufacture end-to-end solutions to improve quality and control production processes in a wide variety of industries. Our systems based on NIR spectroscopy, Hyperspectral imaging, Raman spectroscopy and Machine Vision provide real-time information and results. Visum® brings the laboratory to the production line.

Technologies

Online spectroscopy

We combine NIRS (Near-Infrared Spectroscopy), Hyperspectral Imaging (HSI) and real-time Raman spectroscopy, among other photonic techniques such as UV and fluorescence with artificial intelligence tools and software to develop solutions for the analysis and sorting of food, grains, plastics, organic and inorganic waste, wood panels, pharmaceuticals, chemicals, cosmetics, among a wide variety of materials and mixtures.

Machine Vision & Deep Learning

We use our knowledge in optics, software and engineering to develop machine vision systems and neural networks -or deep learning- to distinguish and classify anomalies, characters and natural variations in complex patterns. Our machine vision systems are used for the control and analysis of defects in grains, nuts, fish, labeling, packaging, among the most popular technology applications.

Benefits

- Real-time monitoring of physical and chemical parameters.

- Industrial use and does not require specialized personnel.

- Possibility of analyzing multiple parameters simultaneously.

- Time savings in laboratory analysis, inputs or visual inspection.

- Real time information to rectify processes and optimize decision making.

- Detection of superficial foreign bodies.

- Reduction of losses, claims and/or returns.

SOLUTIONS BY INDUSTRY

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

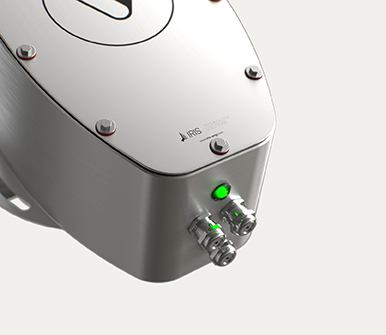

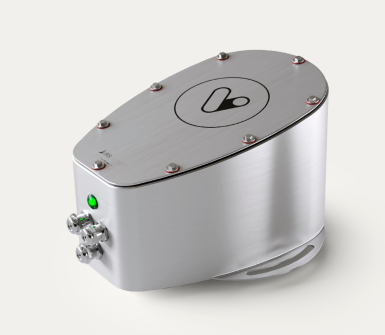

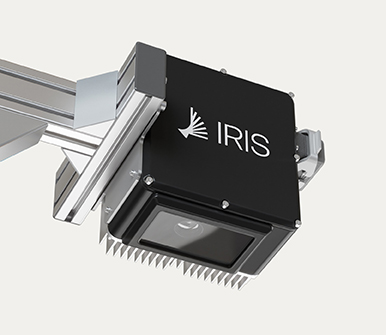

Visum® Devices

Non-destructive, accurate and real-time analytical solutions. Get to know our Visum® line of devices.

WHAT OUR CLIENTS SAY ABOUT US