Quantitative analysis of pharmaceutical forms using NIR spectroscopy

Quantitative analysis of pharmaceutical forms using NIR spectroscopy

Water Activity Analysis in animal feed with Visum Palm™ portable NIR

Water Activity Analysis in animal feed with Visum Palm™ portable NIR

NIRS analysis of Brix degrees in whole apples in real time

Analysis of Brix degrees

The agri-food industry has advanced significantly in recent years through the implementation of technologies to improve quality control and the efficiency of production processes. One of the most relevant technologies in this regard is Near-Infrared Spectroscopy (NIRS). This technology has shown great potential for the non-destructive and rapid analysis of agricultural products, such as apples, allowing the measurement of a wide range of quality parameters. This paper aims to present a detailed analysis of the application of NIRS technology in the continuous analysis of whole Golden Delicious apples with a special focus on analysis of brix degrees, which is the main parameter for controlling the ripening of the fruit, as well as for its preservation and commercialization.

Traditional analysis of brix degrees in apples

The traditional method of analysis of Brix degrees of apples used in the industry is refractometry. Although it is a simple and fairly inexpensive method, it is destructive, off-line, based on random and slow sampling, making it impossible to analyse large volumes of production.

Advantages of NIRS technology

- Non-destructive: Unlike traditional methods, NIRS does not require the destruction of the sample, allowing the fruit to be analysed in its entirety and keeping it suitable for marketing.

- Fast: Analysis is immediate, with response times in milliseconds.

- Multiparametric: A single NIRS analysis can provide information on several quality parameters simultaneously.

- Reduced wastage: By identifying poor quality fruit immediately, they can be diverted before they continue in the packing process, reducing wasted resources.

- Storage optimisation: NIRS technology can identify which fruits have the greatest storage potential, helping companies to better manage their inventories.

Brix analysis of apples with NIR spectroscopy

The following NIRS model for analysis of brix degrees was performed with 40 samples and references of the Golden Delicious apple variety. The spectra and references were obtained from 4 different points (replicates) of each apple from the calibration set with the Visum NIR In-Line™ process analyser. Finally, a digital refractometer was used to obtain the set of reference values.

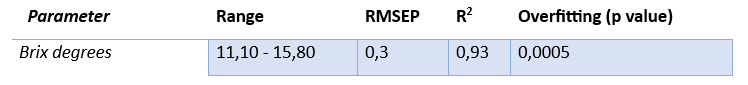

Figure 1: Brix degrees – Key Figures of Merit Visum NIR In-Line™ process analyser

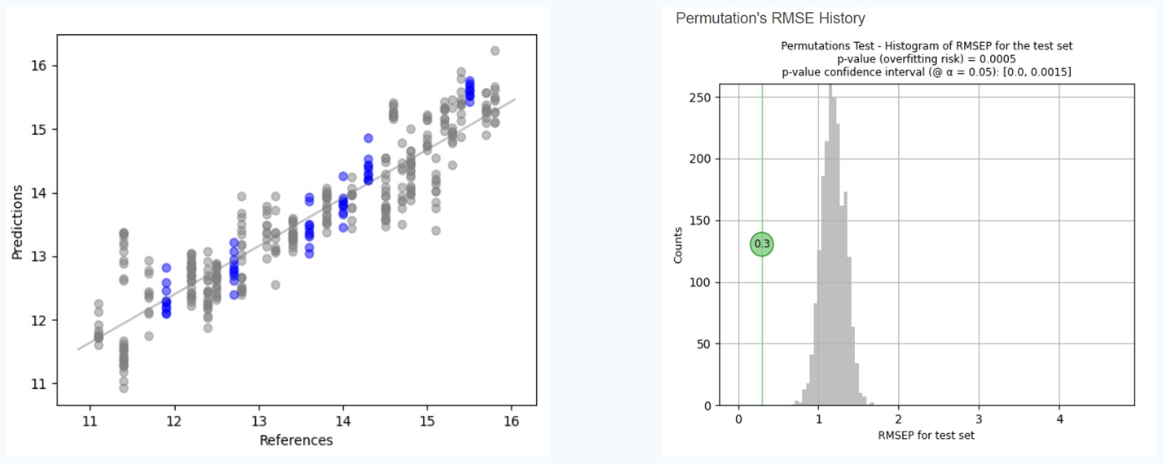

Figure 2: Samples used during model training (grey) and automatically split internal validation samples (blue). Figure 3: Risk of overfitting for the brix model for Golden Delicious apples.

Conclusions: NIRS analysis of Brix degrees

For the sample range of the calibration set (11.1 – 15.8 brix), an RMSEP (Root Mean Square Error of Prediction) of ±0.3 and a correlation coefficient (R2) of 0.93 were obtained with respect to the results obtained using the reference method. The Model Builder Visum Master™ software also automatically runs a spectral quality routine to eliminate spectral outliers , i.e. data that are identified outside the model field during the training phase and finally a permutation test to determine the risk of overfitting, which can be understood as the probability that the calibration performed does not respond adequately to future samples (not used during calibration). For this model the risk of overfitting was only 0.0015, demonstrating the usefulness and accuracy of the Visum NIR In-Line™ process analyser for continuous analysis on apple sorting lines.