NIR in the Woodworking Industry: Particleboard Real-Time Quality Control

NIR in the Woodworking Industry: Particleboard Real-Time Quality Control

Mitigate variations and optimise critical product parameters?

Mitigate variations and optimise critical product parameters?

NIR technology and Raman spectroscopy: introduction and applications in the pharmaceutical industry

In the following article we will address the main applications with NIR technology and Raman spectroscopy, in real time, for the control of manufacturing and quality processes both for pilot plant – in tune with the Quality by Design (QbD) concept – and for industrial scale-up. In addition, this article is intended to be a starting point for industry professionals to raise questions about how to optimize control with process analytical technologies (PAT) for efficient management and implementation of a continuous manufacturing model.

Raman and NIR Spectroscopy

Both technologies have in common that they are photonic techniques – they take advantage of the properties of photons or light and their interaction with matter – diagnostic and non-destructive, allowing chemical and structural information to be obtained in seconds from almost any organic or inorganic material or compound. Hence, their use in laboratories is widespread in different industries and they are analytical techniques known by quality control professionals.

For those who are not laboratory professionals or are just entering the field, it is essential to start with a few brief concepts and examples to understand its applications.

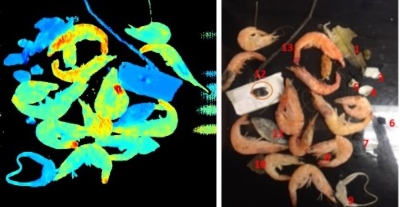

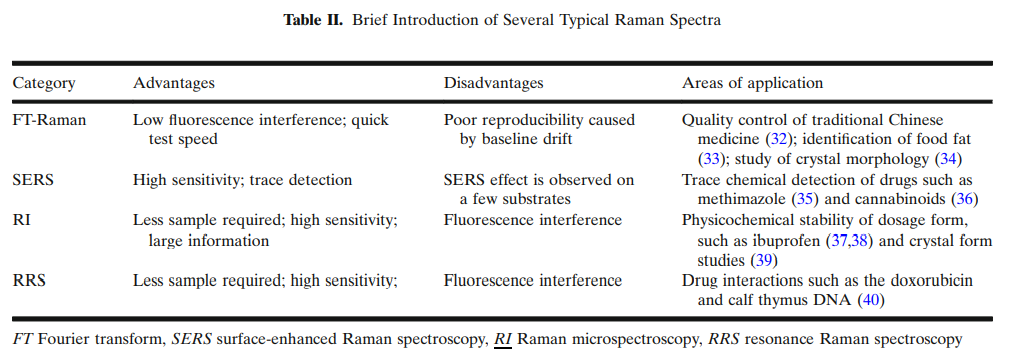

Raman spectroscopy is a technique based on the inelastic scattering of light. Inelastic or Raman scattering occurs when the energy changes during the collision between the monochromatic light and the molecule and, therefore, the frequency of the scattered light also changes. These changes provide information about the molecular identity and structure of the samples or material being analyzed.

Near infrared spectroscopy (NIR) is a technique based on the interaction between electromagnetic radiation and matter, within the wavelength range of 780-2500 nm. These absorbed radiations can be related to different properties of the sample, providing qualitative and quantitative information. The near-infrared range is characterized by weak overtones and combined bands arising from the strong fundamental vibrations of O-H, C-H, C-O, C=O, C=O, N-H bonds and metal-OH groups in the mid-infrared range.

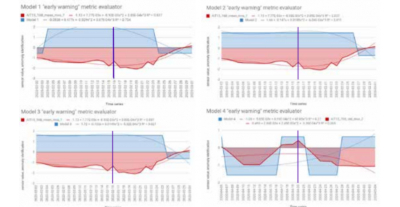

However, both Raman and NIR spectroscopy devices in real time are optical (vision) devices that work with artificial intelligence. The information they collect from the spectrum of the analyzed object is interpreted by a mathematical model – chemometrics – called a “predictive model” that tells the system what it is looking at. A very simple example: if we want to control the Paracetamol content of a 1mg. form, the mathematical model that analyzes the process must know how to correlate the spectrum corresponding to that value and for that it must know what is 0.8 – 0.9 – 1.1 and so on in the range of interest to be controlled. The predictive model is a mathematical model that essentially correlates a spectrum with a reference value. This reference value comes out of the traditional laboratory analysis.

Let’s get down to the important: What use are these systems in my factory?

Applications of real-time NIR technology:

1) Raw material identification: Identification of raw materials is a routine task in the pharmaceutical industry. These tests are carried out before the materials are processed, in order to avoid errors as much as possible and thus save time and money. This material testing applies not only to purchased materials (e.g. excipients), but also to some internal material transfers, e.g. APIs manufactured in another plant. The latter is very important to take into account when wondering why we have problems in mixing some formulations with certain raw materials.

2) Homogenization: Once identified and weighed, raw materials usually require homogenization of the different components. This is a critical step in the manufacture of solid-state pharmaceutical products, as it has a direct impact on the quality and homogeneity of the final product. The homogenization process is mainly affected by physical properties such as particle size, shape and density. Mixing endpoint and homogenization are not the same, not in terms of regulation according to the European Medicines Agency (EMA). From IRIS Technology we try to raise awareness on this point, which is sometimes confused, to provide in-line control solutions that are homologous to the control protocols established by the EU and Spanish regulations.

3) Granulation and sizing: Sometimes the different ingredients of the formulation do not mix well and segregate during homogenization. Therefore, it is desirable to granulate powdered ingredients by compression, dry granulation or in the presence of a binder under wet conditions. Most spectroscopic uses focus on the determination of water during wet granulation or drying after granulation.

4) Extrusion: NIR spectroscopy has been widely used in hot extrusion to monitor both API content and solid state of extrudates and to identify interactions between ingredients.

5) Tableting: This stage of the process is the closest to the final product. Therefore, it is sometimes easier to control the quality of the product directly in the press, especially if there is a subsequent coating step. At this point, NIR can also play an important role.

6) Coating: The coating process is a crucial step in the manufacture of solid oral preparations. In fact, the coating can act as a physical screen to avoid the effects of oxidation, moisture and lighting conditions in order to improve the stability of the final product or intermediate products in the process. The coating can also play an active role in the protection (gastroresistance) and release (modified release) of the drug in vivo. The homogeneity and thickness of the coating are important in controlling the timing of drug release. Many offline techniques are available to control the coating thickness, such as changes in weight, height or diameter of the coated granule/tablet cores during processing. In-line NIR technology is especially useful for monitoring water-based coatings and is a technique that saves hours of analysis, which we have discussed in particular in this other article.

7) Final product control: An important part of final product quality control includes the analysis of all batches produced to avoid out-of-specification results. This control point, although it is too late to avoid losses, can also be performed with portable (handheld) NIR tools and in just seconds analyze dozens of units (homogeneity, concentrations or other parameters) at the line.

Real-time Raman spectroscopy applications

As we will see below, this analysis technique has some applications similar to NIR spectroscopy and others very different because it is a technique with a much higher precision than NIR and that IRIS Technology uses in the systems we manufacture when we work with APIs with very low concentrations (typically <0.5) or in aqueous matrices where the amount of water generates a lot of noise in the analysis with NIR equipment.)

1) Raman spectroscopy for API identification: As each API has its own Raman characteristics, Raman spectroscopy can quickly and accurately identify the active ingredients, has a very low prediction error and in some cases has a detection limit as low as ppm.

2) Raman spectroscopy for the quantitative and qualitative analysis of formulations: The composition of pharmaceutical preparations is relatively complex; however, Raman spectroscopy remains one of the rapid detection methods if the excipients are simple or just an aqueous solution.

3) Raman spectroscopy for detection of illicit substances: Raman spectroscopy can be used for trace detection due to its sensitivity, speed and accuracy. In general, small amounts of illicit drugs cause drug safety incidents, and Raman spectroscopy can be used for illicit drug detection.

Benefits of applying NIR and Raman technology in production lines

In general, there are two fundamental advantages of Raman spectroscopy and NIR technology on production lines over traditional laboratory methods:

The first advantage would be the monitoring of continuous manufacturing. The pharmaceutical industry works mainly in such a way that the final drug is the result of several independent production steps. These can also take place in different geographical areas, which entails shipping and storing the different intermediate products in containers until the next manufacturing facility. This increases the risk of degradation over time or due to environmental conditions (light, humidity, etc.). One way to address this problem is to move from independent batch work to continuous manufacturing with the help of monitoring technologies such as real-time analytical control equipment.

A continuous process or continuous manufacturing is one in which materials are continuously loaded into the system, while the final product is continuously unloaded. Unlike stand-alone batch manufacturing, this concept involves the total connection of production units, with the use of PAT systems, along with process control systems to monitor and control the integrated manufacturing plant. Continuous process units are usually more efficient, more productive, with reduced volumes and less waste compared to classical process units. Therefore, these types of production units can respond more quickly to drug shortages or sudden changes in demand or needs (such as in a pandemic). In addition, their small size allows them to be transported directly to where the drugs are needed. However, a thorough understanding of the process, including the different connections between its processing units, is necessary.

The second major advantage is to reduce sampling and analysis time, and this is very important in biotech processes in their research, development and production phases. So far, most of the data are obtained with off-line instruments and methods.

Specifically for Raman, Raman spectroscopy is a powerful instrumental technique used in various types of pharmaceutical analysis. The superiority of the technique depends on the molecule of interest, the concentration level, the matrix or solution, other interfering species present and the desired sampling method. For many applications, Raman spectroscopy may be the best answer for identification and spectroscopic control needs. The role of Raman spectroscopy as a quantitative analytical tool is increasing due to the simplicity of sampling, ease of use and applicability to aqueous systems.

As manufacturers and system integrators of systems that operate with Raman and NIR spectroscopy, IRIS Technology collaborates with numerous pharmaceutical, foodstuffs, chemicals, among others, companies in the development of analytical solutions and the implementation of control systems, in turnkey projects ranging from technology, adaptations that may be necessary, data modeling, installation, validation and even homologation.

Here you can find the complete range of Visum® analytical equipment.

We hope this article has been of interest to you and as always, if you have any questions or even suggestions, you can write to us at news@iris-eng.com.