Controllo del processo di rivestimento di forme granulari mediante spettroscopia NIR

Controllo del processo di rivestimento di forme granulari mediante spettroscopia NIR

Monitoraggio in tempo reale del lattide libero durante la produzione di PLA (acido polilattico)

Monitoraggio in tempo reale del lattide libero durante la produzione di PLA (acido polilattico)

Analisi della plastica con NIR Visum Palm™: Precisione, Agilità e Versatilità per l’Industria

Analisi della plastica con NIR Visum Palm™

L’analisi della plastica e la sua classificazione sono diventate più cruciali che mai, spinte da nuove normative e pratiche ambientali, in numerosi settori: dai produttori di materiali e operatori del recupero dei rifiuti ai riciclatori, rottamai e aziende che lavorano plastiche riciclate.

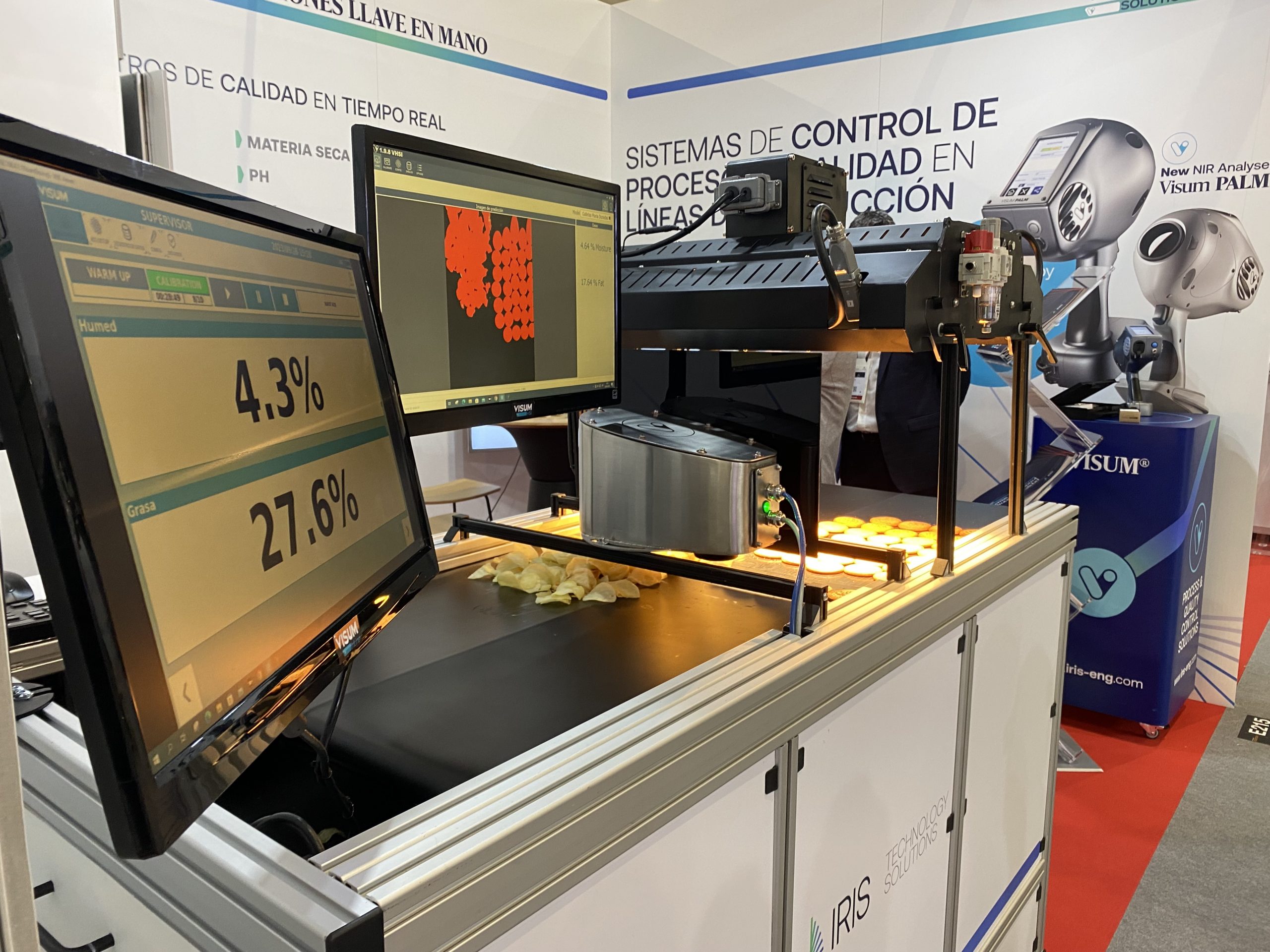

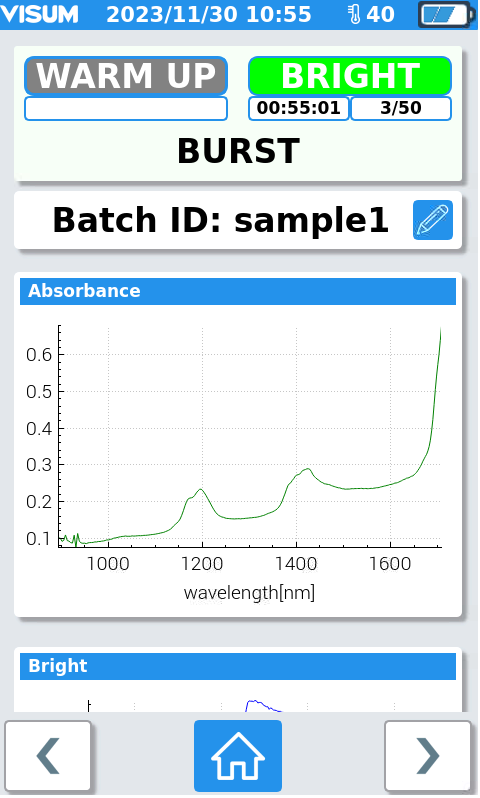

In questo contesto, l’analizzatore portatile NIR Visum Palm™ si distingue come uno strumento ideale per un’identificazione rapida e precisa della plastica in tempo reale, indipendentemente dal tipo di campione: rifiuti, fogli, granuli vergini o riciclati, scaglie e altro ancora. Visum Palm™ è un analizzatore autonomo, il che significa che include un computer integrato, software e touchscreen, e non necessita di alcuna connessione a dispositivi esterni come PC, tablet o smartphone.

Il dispositivo è preconfigurato con una libreria gratuita per l’identificazione della plastica, contenente 39 classi e coprendo i polimeri più comuni. Può essere utilizzato come dispositivo portatile per l’analisi della plastica a contatto diretto oppure come strumento da banco in laboratorio o nell’area di ricezione dei materiali, grazie a diversi supporti per campioni adatti a vari tipi di analisi e formati.

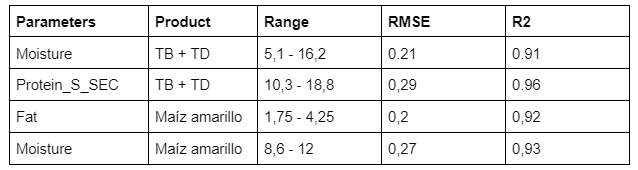

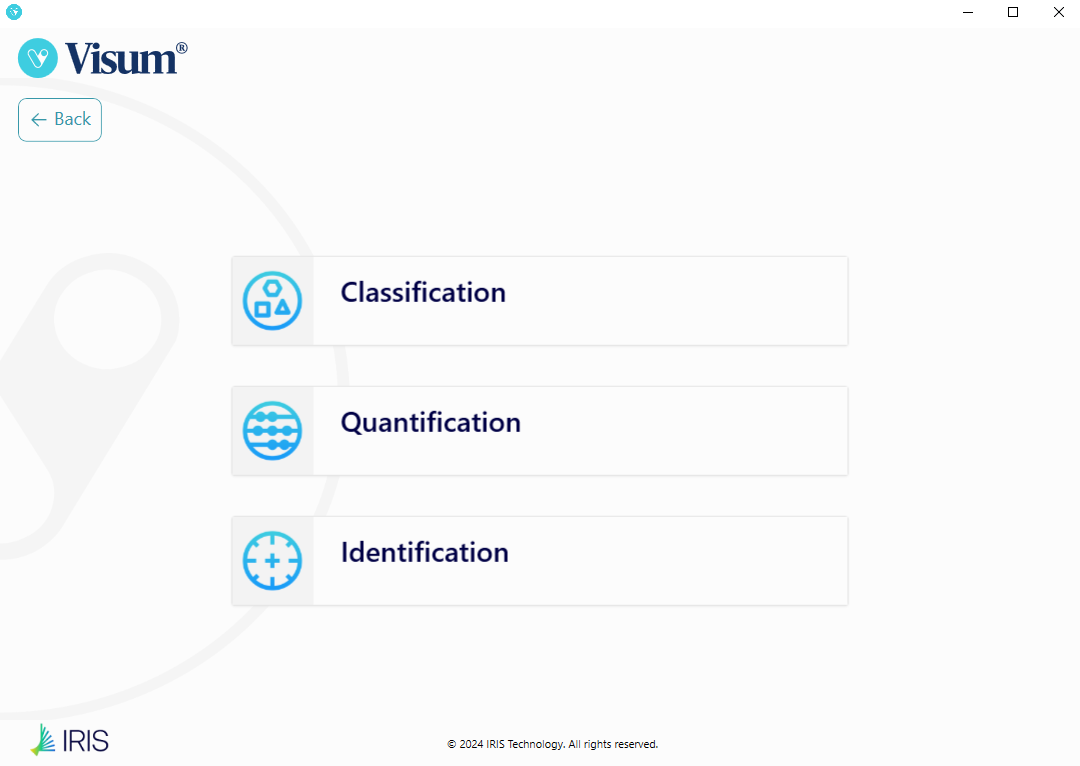

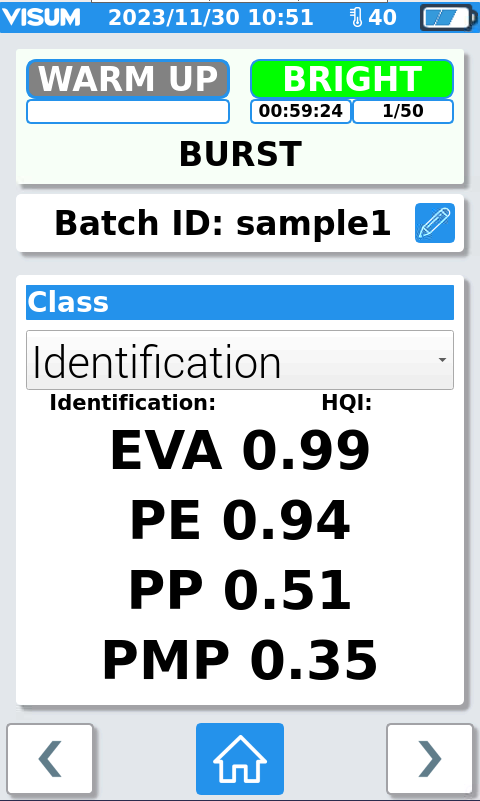

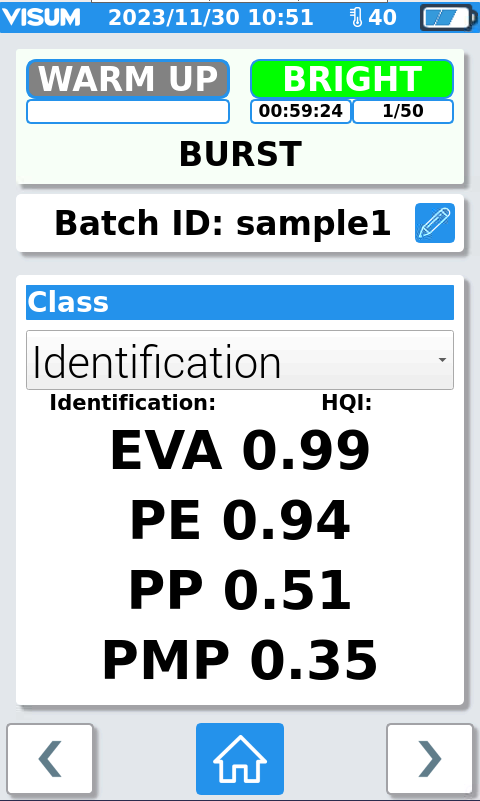

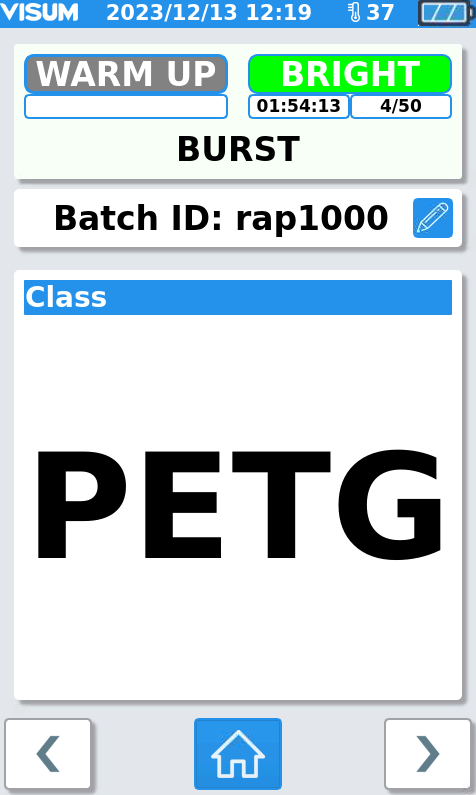

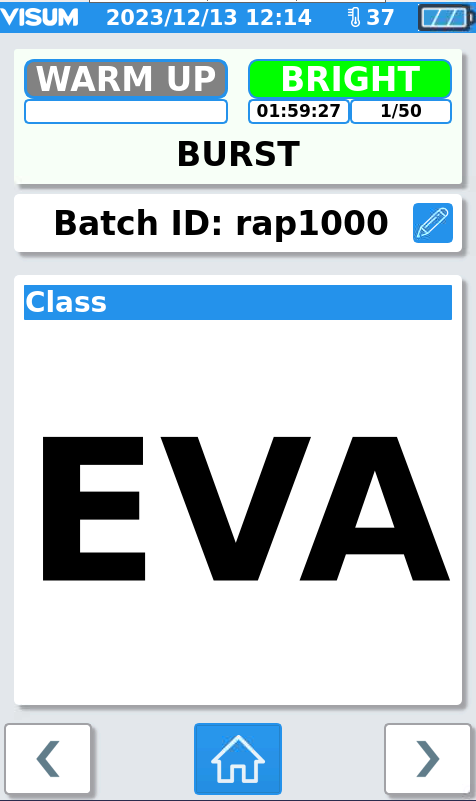

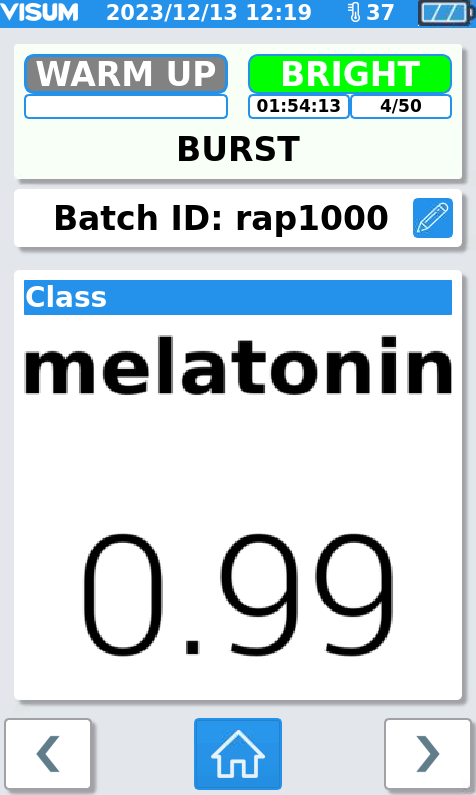

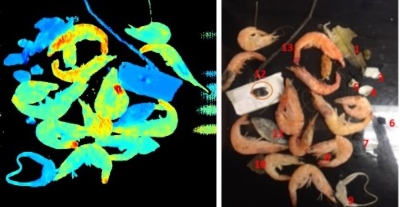

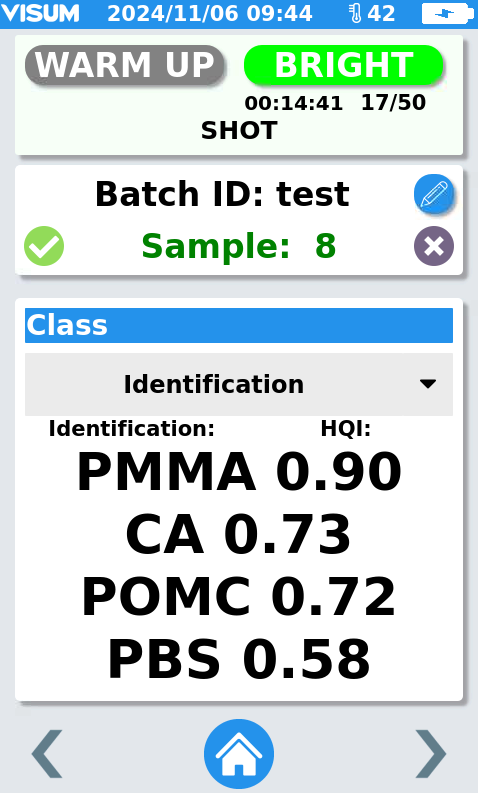

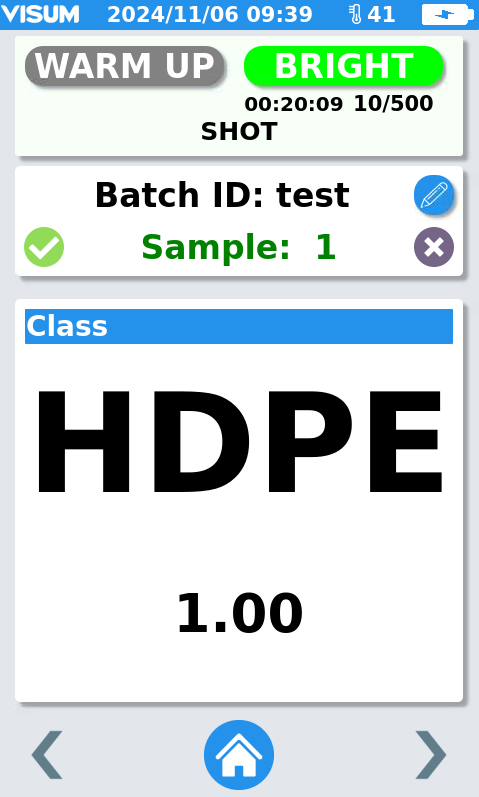

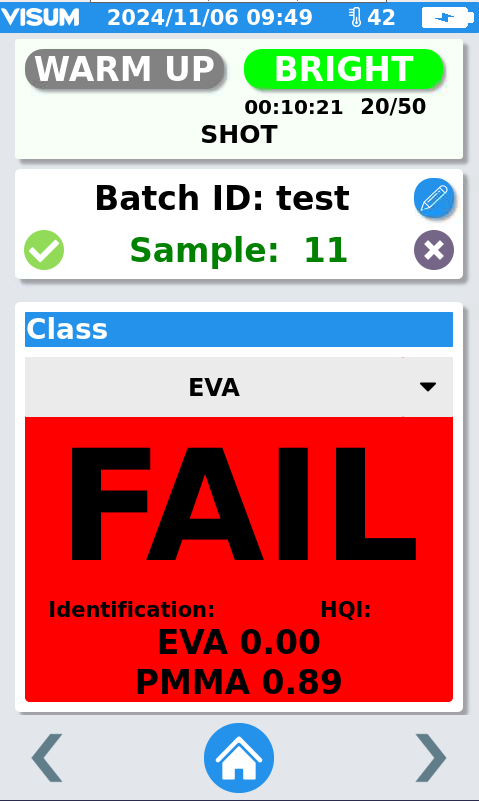

Modalità di analisi della plastica: Identificazione (a sinistra) e classificazione (a destra)

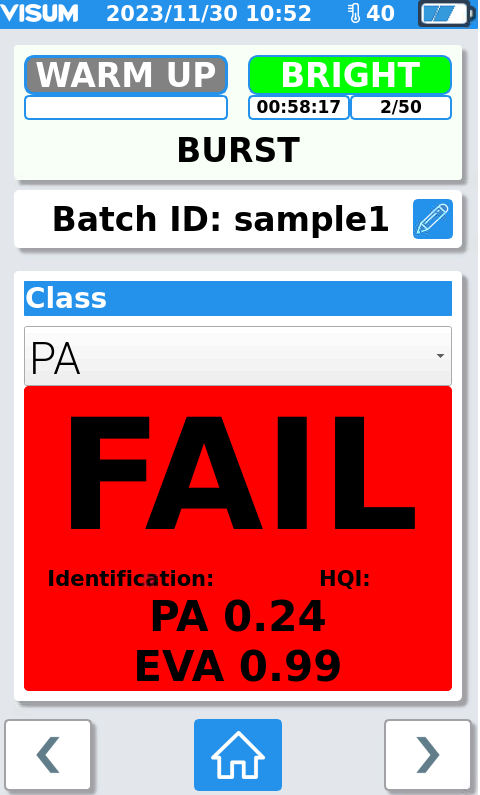

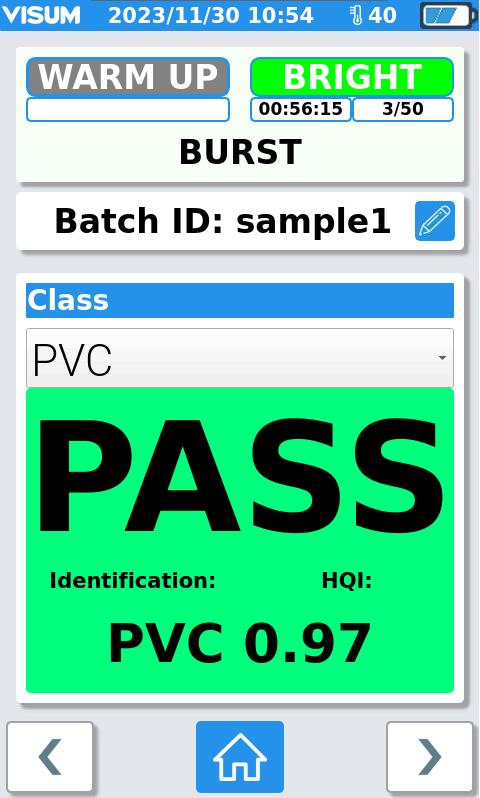

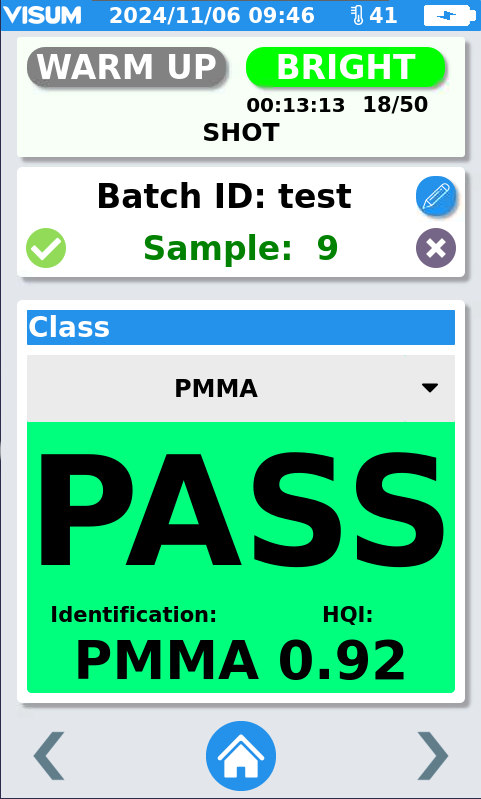

Modalità di analisi della plastica: Verifica (SUPERATO/NON SUPERATO) e materiale corretto

What Plastics Can Visum Palm™ Identify—and What Are Its Limitations?

Come già accennato, Visum Palm™ include una libreria con 39 classi di plastiche, tra cui:

PMMA, PE, PC, PETG, EVA, PVC, PET, PU, PS, ABS, PA, PP, VIN, PLA, PBT, PMP, POMC, PPS, PVA, PPSU, EMA, PHBV, PAEK, PBAT, PBS, TPES, TPS, MABS, HIPS, MBS, SBC, PCL, PEEK, PHB, SAN, PI, PB, HDPE, LDPE.

Questa libreria viene aggiornata periodicamente per garantire una copertura ottimale e prestazioni elevate nelle applicazioni reali.

L’analizzatore è compatibile con un’ampia gamma di tipologie di campioni, rendendolo uno strumento estremamente versatile per l’analisi della plastica:

-

Rifiuti plastici post-consumo: sacchetti, bottiglie, vasetti e vari componenti. In presenza di sporco superficiale, si consiglia una pulizia minima. Grazie al suo intervallo spettrale di 900–1700 nm, un’area di misura di 10 mm e un’illuminazione intensa, Visum Palm™ offre una penetrazione minima, risultando meno sensibile allo sporco o ai rivestimenti rispetto agli strumenti a gamma estesa che analizzano solo la superficie.

-

Granuli (vergini o riciclati): possono essere analizzati in modalità da banco con appositi portacampioni.

-

Scaglie: ideali per le linee di riciclo dove è necessaria una rapida classificazione del tipo di polimero.

-

Pezzi di plastica di varie dimensioni e geometrie: la forma del campione può influenzare la qualità spettrale; è quindi importante prestare attenzione ai pezzi curvi o irregolari per evitare letture anomale.

-

Polveri e liquidi: possono anch’essi essere analizzati, a condizione che si utilizzino i portacampioni adeguati – ne sono disponibili diversi.

L’analisi della plastica con Visum Palm™ è così applicabile a un’ampia varietà di scenari, sia nel laboratorio che in ambienti produttivi.

Limitazioni dell’analisi della plastica con Visum Palm™

Come tutte le tecniche analitiche, anche la spettroscopia NIR presenta limitazioni intrinseche legate al suo principio fisico di rilevamento e all’intervallo spettrale di 900–1700 nm utilizzato da Visum Palm™. In alcuni casi, l’analisi della plastica può risultare inaffidabile o non applicabile:

-

Plastiche nere contenenti nerofumo: questo additivo assorbe completamente la luce NIR, rendendo la tecnica inefficace.

-

Plastiche che richiedono un rilevamento al di fuori dell’intervallo spettrale: alcuni polimeri necessitano di una gamma spettrale più ampia per un’identificazione sicura.

-

Microplastiche e frammenti molto piccoli (< 2 mm): le dimensioni ridotte impediscono una corretta acquisizione dello spettro.

-

La spettroscopia NIR è una tecnica empirica: gli spettri devono essere interpretati e confrontati con un database di riferimento. Per questo motivo, è sempre consigliata una valutazione individuale in presenza di campioni complessi o simili tra loro.

In scenari in cui le differenze tra i materiali sono minime, Visum Palm™ consente la creazione di modelli di classificazione dedicati, utilizzando algoritmi matematici avanzati. Questo migliora la precisione dell’analisi della plastica grazie a un secondo livello di verifica.

Crea e gestisci la tua libreria personalizzata – Analisi della plastica

La nostra esperienza sul campo conferma che la variabilità dei campioni plastici è molto ampia, sia per tipo di polimero, forma, colore, rivestimento o origine (vergine, post-consumo o riciclata). Sebbene la libreria integrata venga aggiornata regolarmente, è impossibile coprire tutte le combinazioni possibili.

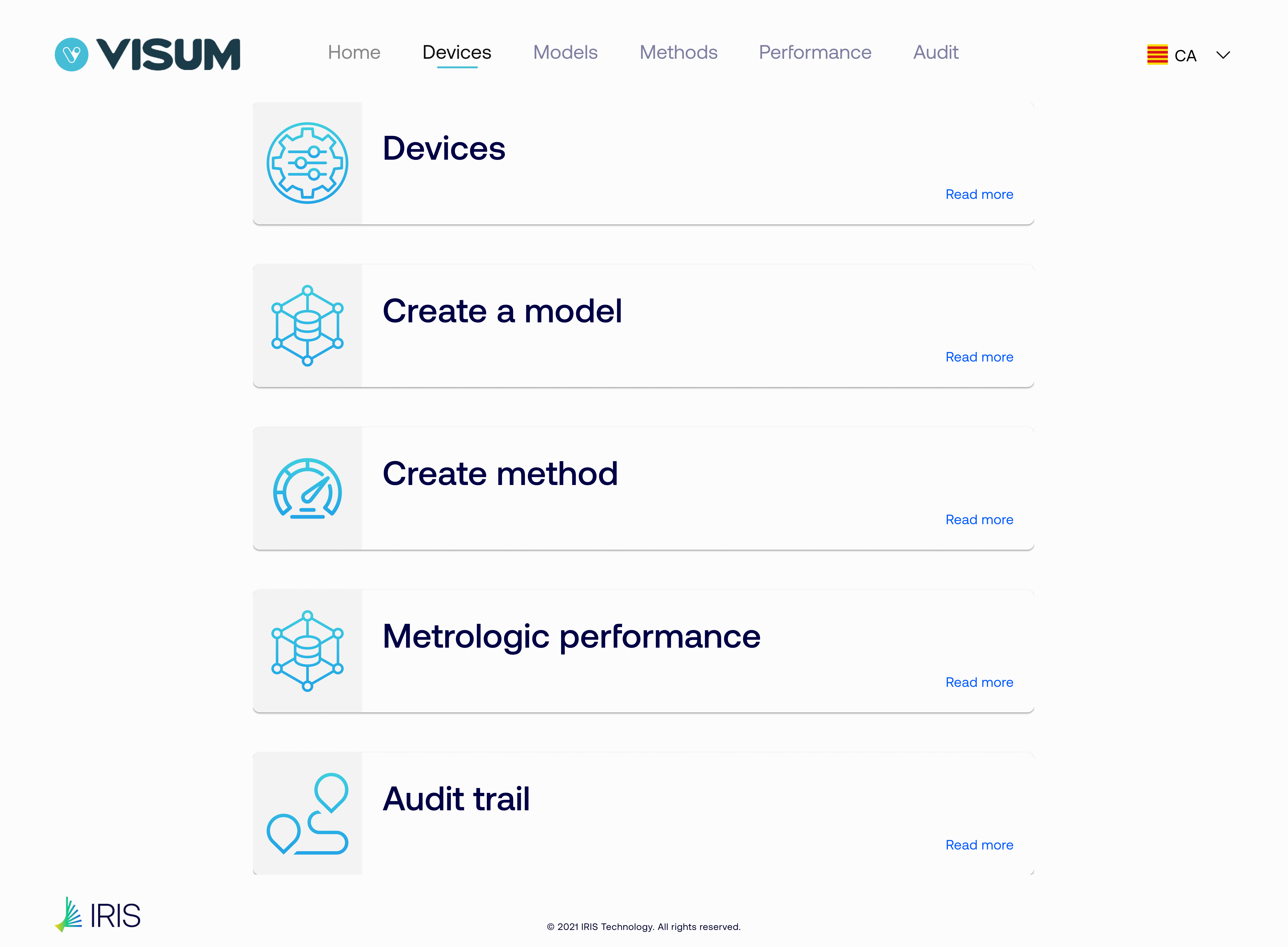

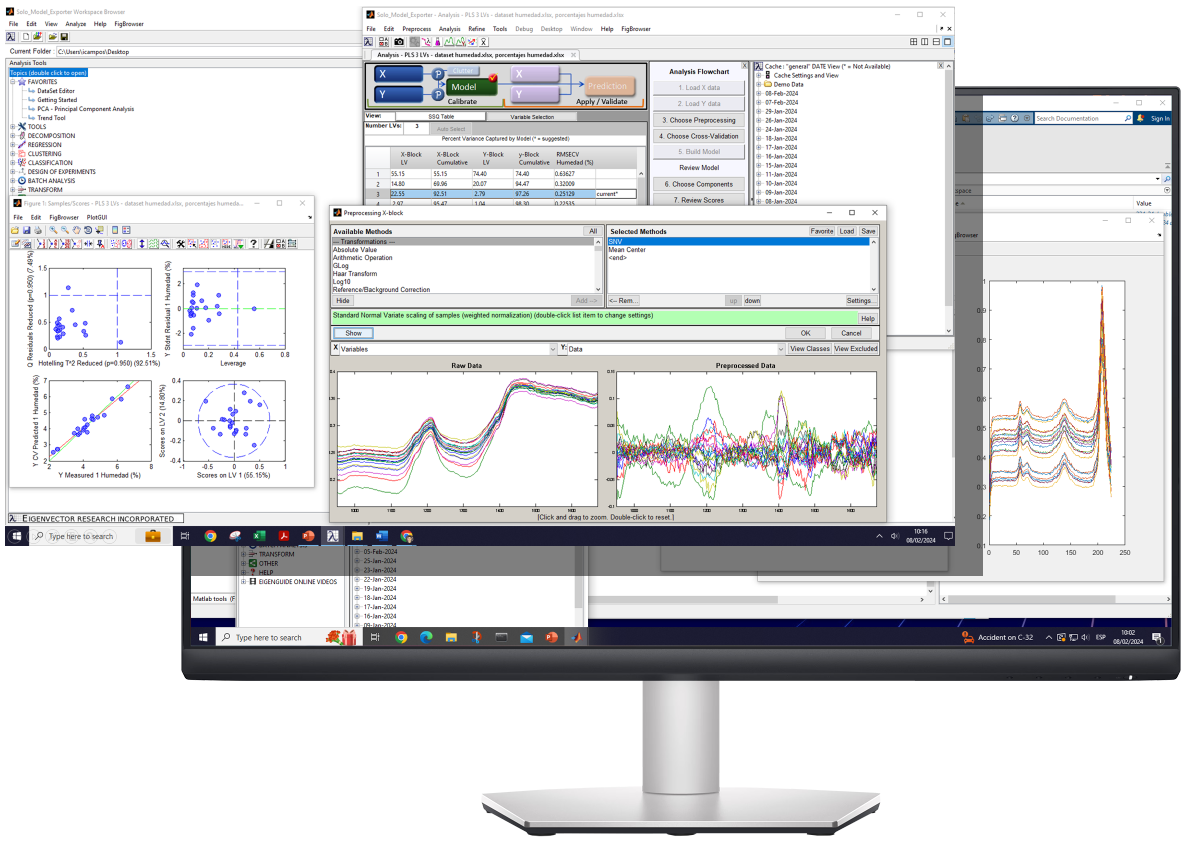

Per questo motivo, ogni dispositivo è fornito con il software per PC Visum Master™ SMART, che consente agli utenti finali di:

-

Ampliare la libreria esistente con i propri campioni

-

Aggiornarla continuamente, senza la necessità di conoscenze tecniche in spettroscopia

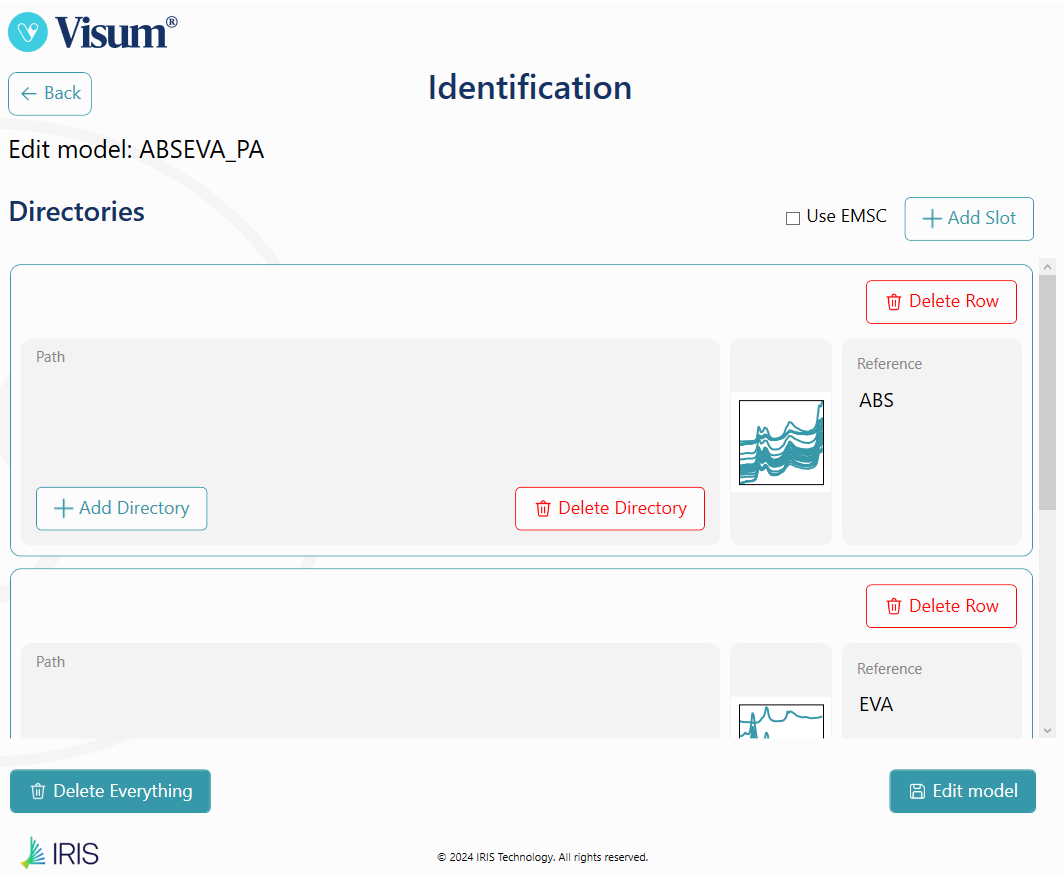

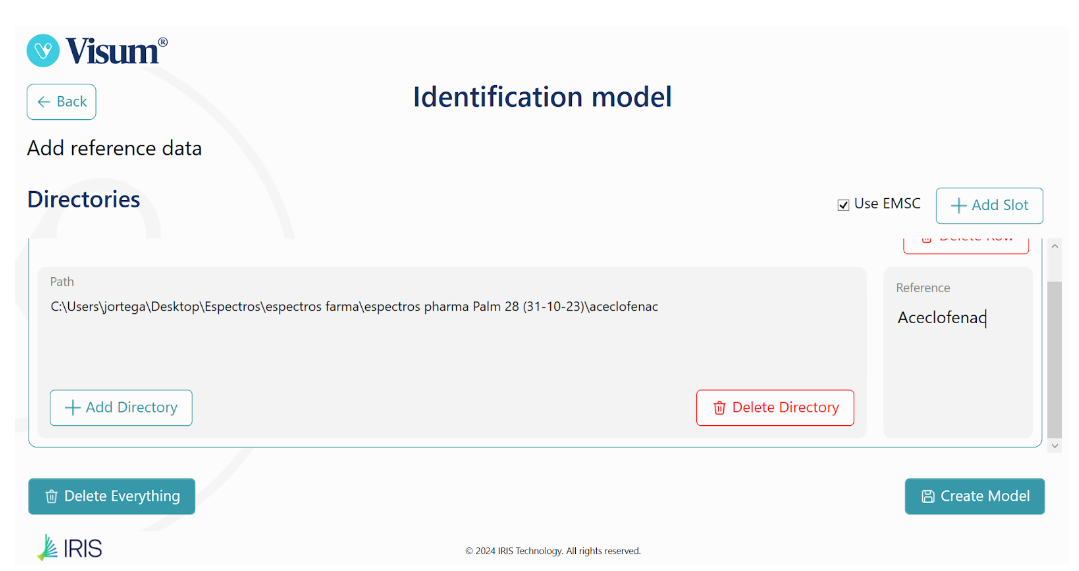

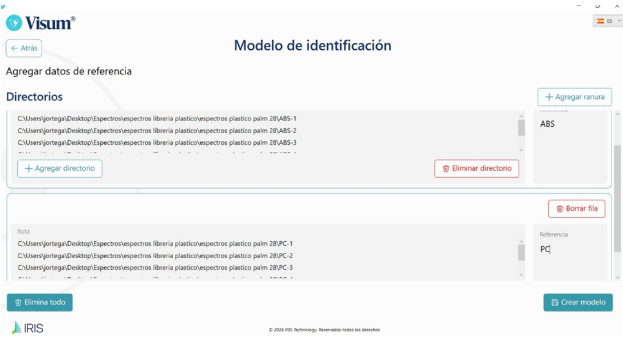

Di seguito è riportato un esempio di come viene creata o aggiornata una libreria personalizzata per l’analisi della plastica: il processo prevede l’acquisizione di spettri da diverse classi e varianti in termini di forma, colore e caratteristiche superficiali, seguita dall’assegnazione del nome corretto del materiale.

Analisi della plastica con Visum Master™: Sviluppo o aggiornamento di una libreria di identificazione o classificazione con Visum Master™ SMART.

Questo consente a riciclatori e produttori di costruire in modo autonomo una libreria solida, aggiornata e rappresentativa del proprio processo, su misura per le loro esigenze specifiche.

Conclusione

Visum Palm™ offre una soluzione pratica, precisa e versatile per l’analisi della plastica, l’identificazione e la classificazione in ambienti industriali. La sua portabilità, semplicità d’uso e compatibilità con diversi tipi di campioni – dai rifiuti e granuli fino a scaglie e componenti – lo rendono uno strumento prezioso sia per i laboratori che per le linee di produzione.

Sebbene la tecnologia NIR presenti alcune limitazioni – in particolare con plastiche nere, materiali altamente caricati o formulazioni specifiche – la possibilità di creare librerie e classificazioni personalizzate con Visum Master™ SMART rende questo sistema altamente adattabile a quasi tutti i contesti produttivi.

In un mondo in cui la tracciabilità e la corretta separazione dei materiali sono sempre più fondamentali, Visum Palm™ si afferma come uno strumento strategico per le aziende che desiderano migliorare i propri processi di riciclo, il controllo qualità o i flussi di identificazione rapida dei polimeri.