Mitigate variations and optimise critical product parameters?

Mitigate variations and optimise critical product parameters?

IRIS Technology develops the first industrial system for the chemical control and inspection of melamine boards

IRIS Technology develops the first industrial system for the chemical control and inspection of melamine boards

Artificial Intelligence as a Predictive Maintenance tool

Artificial Intelligence as a Predictive Maintenance tool

Together with the company mAbxience, specialized in the development, manufacture and marketing of biopharmaceuticals, we developed data models based on supervised machine learning techniques that after 4 years of work resulted in an AI-based Predictive Maintenance System in the plant facilities of the water for injections (WFI) process of mAbxience in Spain, published in the January-February Edition of the Pharmaceutical-Engineering Magazine.

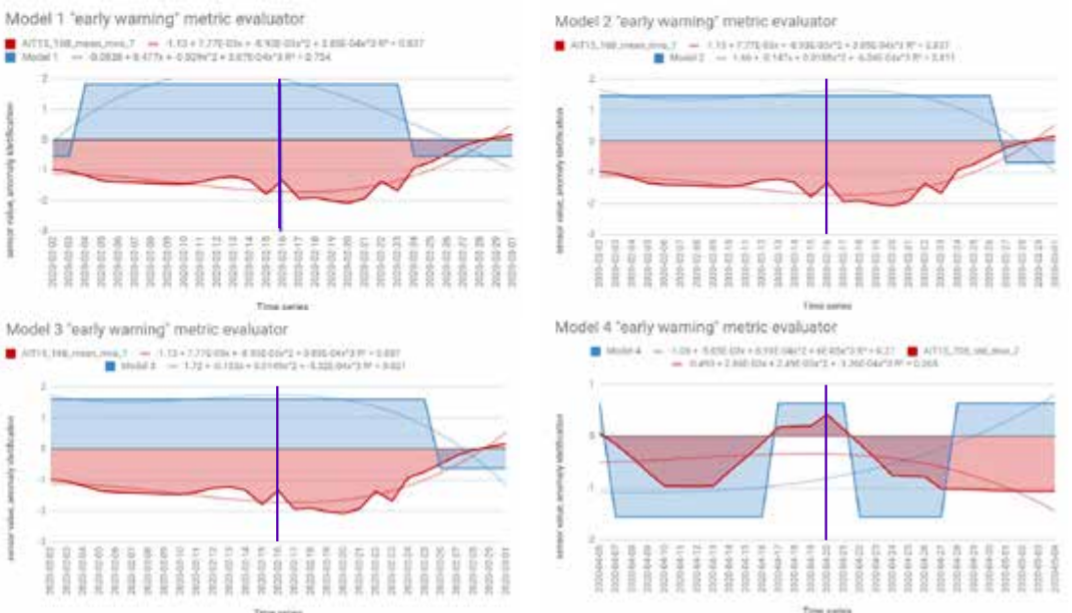

The work demonstrates the effectiveness of machine learning models, built from the information generated by 31 sensors, 14 alarms and water quality indicators, to identify and predict anomalies within a warning time window (14 days) that is feasible for the preventive and predictive maintenance teams to make the corresponding adjustments in the areas and components of the plant identified by the algorithm.

Initial results show that the models are robust and able to identify the chosen anomalous events. In addition, the rule induction approach to machine learning (a technique that creates “if-then-else” rules from a set of input variables and one output variable) is “white box”, which means that the models are easily readable by humans and can be deployed in any programming language.

IRIS thanks mAbxience and the WFI plant technicians for their collaboration.

Read the full article here.