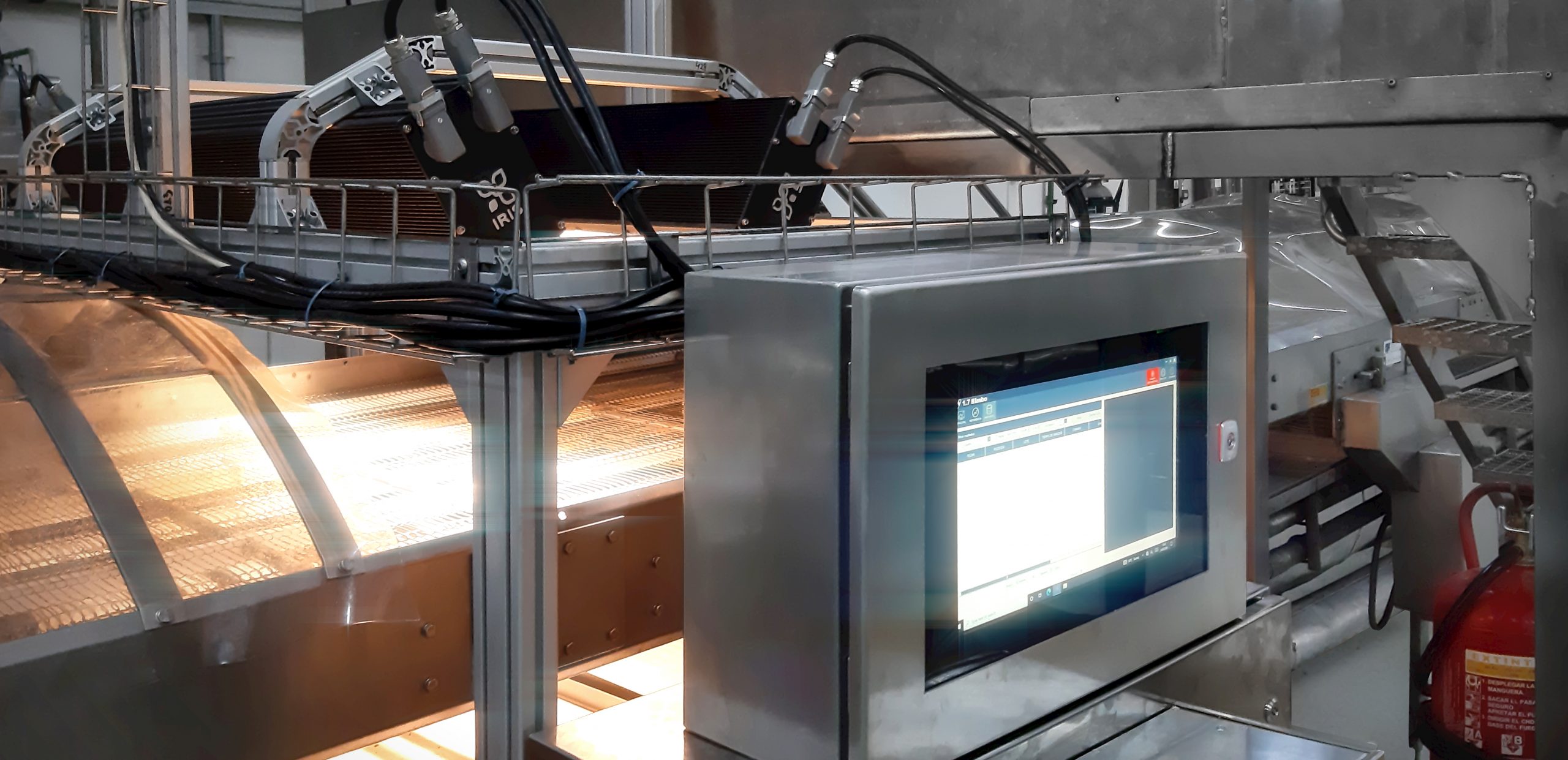

Visum DeepSight™ - Machine Vision System

The Machine Vision System Visum DeepSight™ detects, classifies and rejects. Delivers the best quality every time.

REQUEST A QUOTEMachine vision system for real-time monitoring

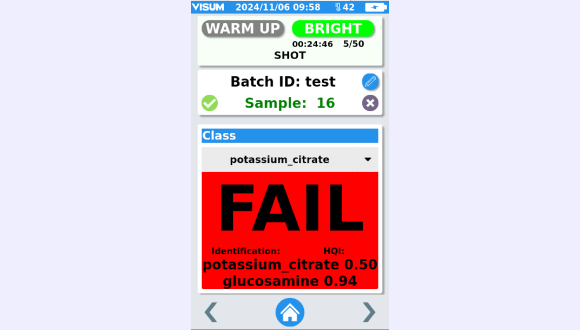

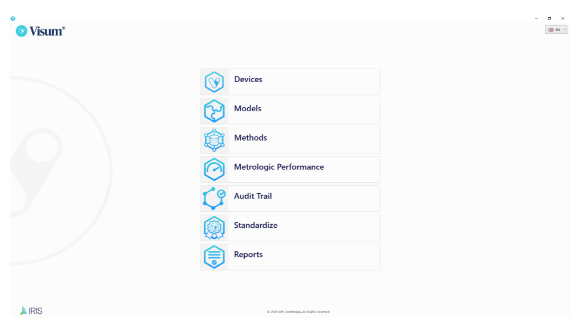

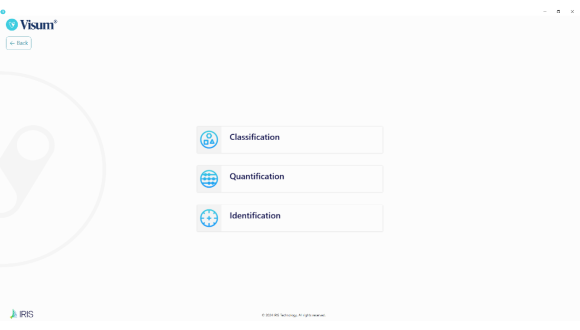

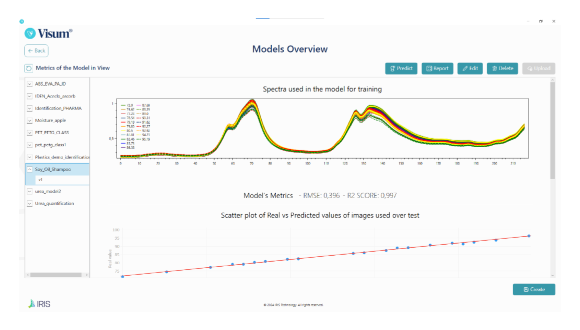

The Visum DeepSight™ vision system is an industrial vision system supported by deep learning for colorimetric and morphological quality control and detection of complex defects and indeterminate changes in various products.

TURNKEY SOLUTIONS

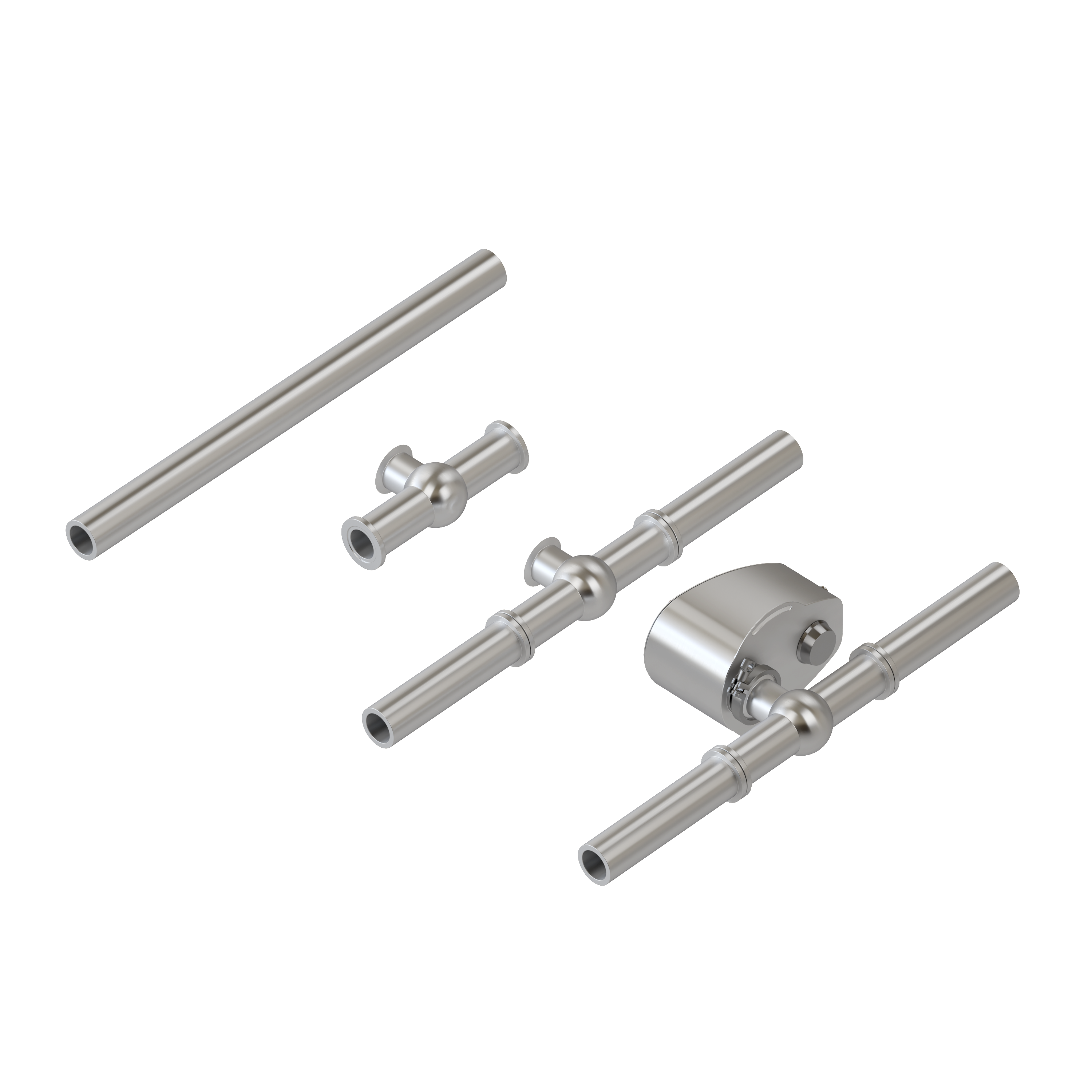

Deep learning technology and the Visum DeepSight™ machine vision system, unlike deterministic algorithms, enables results where traditional machine vision systems cannot and has many applications in industry, such as detecting foreign bodies or defective units in food, inspecting packaging, labeling, unacceptable color differences in different products - even textiles, plastics, ceramics - or objectively quantifying defects or flaws to calculate a fair price for different product quality classes. IRIS Technology develops turnkey industrial vision systems for a wide range of applications. Visum DeepSight™ is a machine vision system that combines machine learning models and algorithms with lighting and optical systems, the result of more than a decade of industry leadership and accompanying the industry through various challenges.

Main features

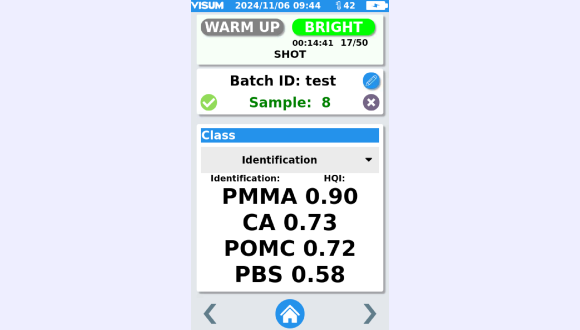

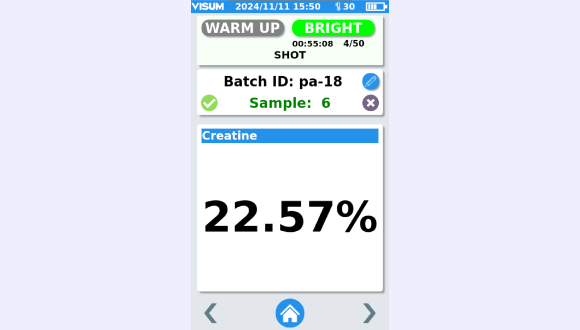

- Detection of quality defects for sorting or rejection.

- Detection of surface foreign bodies.

- Classification and quantification of defects.

- Fast and cost-effective integration into the production line.

- Communication with information systems.

- Antireflex system.

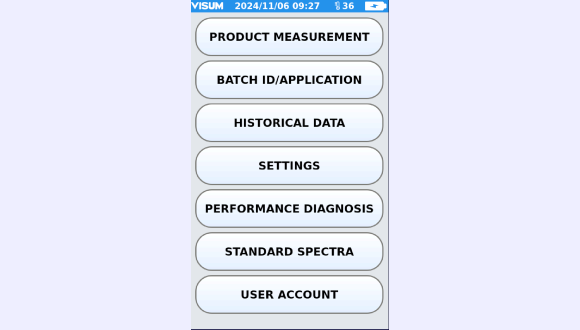

- Visum® software, computer system and touch screen.

Sectors

Food

- Inspection of defects in grains, dried fruits, fish fillets.

- Detection of foreign bodies on the belt and in the product.

Other Industries

- Label inspection.

- Bottling control.