Circular Economy: Bioplastics vs. black plastics

Circular Economy: Bioplastics vs. black plastics

Thickness control of multilayer films with Visum® technology

Thickness control of multilayer films with Visum® technology

Detection of foreign bodies in the production line

Detection of foreign bodies in the production line

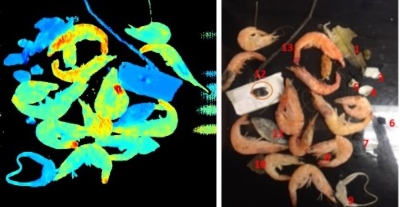

In this post we will address a recurrent and transversal problem in the industry related to food safety and security: the presence of foreign bodies in the production line and we will see how we can prevent this from happening with viable techniques at industrial level such as imaging spectroscopy or also known as Hyperspectral NIR or Hyperspectral Imaging (HSI).

What do we mean by foreign bodies?

In general terms, for manufacturers, „foreign body“ is anything that should not be in the production line, whether it is an organic element (bone, skin, shells, other food that is not the product to be packed, pieces of wood, wood chips to mention a few) or inorganic elements such as metals, screws, plastics, cardboard, paper, etc. The rule is that everything that is not product should not be there, as it is a problem that can alter the quality of the final product and therefore generate economic losses, as well as being a risk for the health of consumers and the image of the company.

State of the art

Until now, foreign body control in the vast majority of industries, whether food or non-food, has been carried out by visual inspection. That is to say, with operators on the production line watching the product flow and extracting any foreign bodies that may have crept in during the manufacturing process. On the one hand, X-ray detection systems, which have already been implemented in practically all industries, guarantee that no conductive elements, i.e. metals, will pass through the line, but do not exempt us from the possibility of non-conductive and low-density elements such as plastics, paper, cardboard, stones, glass, rubber, among others, which may appear and which are undetectable with this technology.

On the other hand, traditional machine vision, for the detection of foreign bodies, has important limitations due to the enormous variability that can exist in terms of type, shape, colour or size, which results in a high false positive rate (rejected „good“ product). However, on a more contemporary level, artificial vision assisted by deep learning or machine learning algorithms is a technology that has its benefits at certain points in the line, such as in packaging, where it is useful for detecting the presence of certain physical contaminants.

Foreign body detection with hyperspectral NIR

If we have to say that by 2022 there is a sufficiently mature, easily integrated online and economically viable technology for detecting foreign bodies, it is hyperspectral NIR technology.

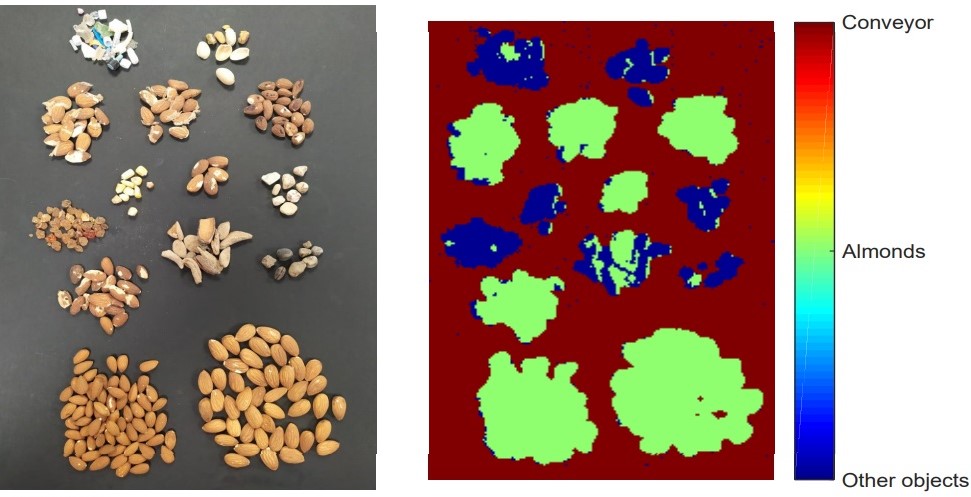

This technology is an extension of traditional machine vision in two ways: Firstly, instead of the usual three colour channels in machine vision, hyperspectral imaging uses up to hundreds of channels, making it possible to see very subtle differences. Secondly, hyperspectral cameras incorporating these systems often have an extended spectral range beyond the visible, i.e. into the infrared, where chemical composition is much more evident than in the visible range.

Hyperspectral imaging can therefore be seen as a paradigm shift in vision systems and as a source of abundant, high-quality data to feed vision systems based on artificial intelligence algorithms. In practice, having a hyperspectral camera is equivalent to having a spectrophotometer in each pixel, i.e. it allows obtaining chemical information on the composition of the product pixel by pixel and product unit by product unit, providing a clear image of the whole inspected area and distinguishing according to its chemical composition what is product and what is not, regardless of its shape, size or typology. It has a limitation; as it works with light and as this has a minimum penetration in the material, everything that is not superficial will not be detected. To prevent this from happening, at IRIS Technology, we integrate vibration or velocity to generate dispersion of the product in the section where the hyperspectral detection system is located.

The Visum HSI™ system can operate at a speed of up to 50 m/min detecting foreign bodies up to 3 mm² and with a minimum density of 0.7g/cm³. It is therefore a „compromise“ solution between line speed, processing power and minimum detectable size.

Visible NIR and chemical composition

IRIS Technology’s turnkey systems, such as the Visum HSI™ analyser, can operate in two spectral ranges, Vis-NIR (400 to 1000 nm) or SWIR (900-1700 nm). The application of one camera or the other in the hyperspectral system will depend on the manufacturer’s need. If it is only a question of detecting foreign bodies, a Vis-NIR camera will be used, since in this range there is enough chemical information to detect what is a product and what is not. On the other hand, if you also want to quantify or classify product composition parameters other than moisture, such as fats, proteins, fibres, acidity or other parameters, a camera working in the SWIR range will be used to obtain reliable and robust results like those of the laboratory.

Some final clarifications

It is important to note that hyperspectral technology is not useful for detecting foreign bodies inside the product, regardless of the product in question, because as mentioned above, the light has minimal penetration.

Although it is not the subject of this article, we believe it is important to clarify that hyperspectral technology is also not useful for the detection of microbiological activity at the concentrations and limits required by regulatory bodies (ppm), where the only viable analytical technique is still the swap or Elisa.

Therefore, at IRIS Technology we are constantly investing in R&D to increase the analytical capabilities of our systems, as well as to develop advanced solutions that are reliable and feasible to integrate into the production line.