Plastic identification, verification and classification using Visum Palm™

Plastic identification, verification and classification using Visum Palm™

Real-time monitoring of free lacticide during the production of PLA (polylactic acid)

Real-time monitoring of free lacticide during the production of PLA (polylactic acid)

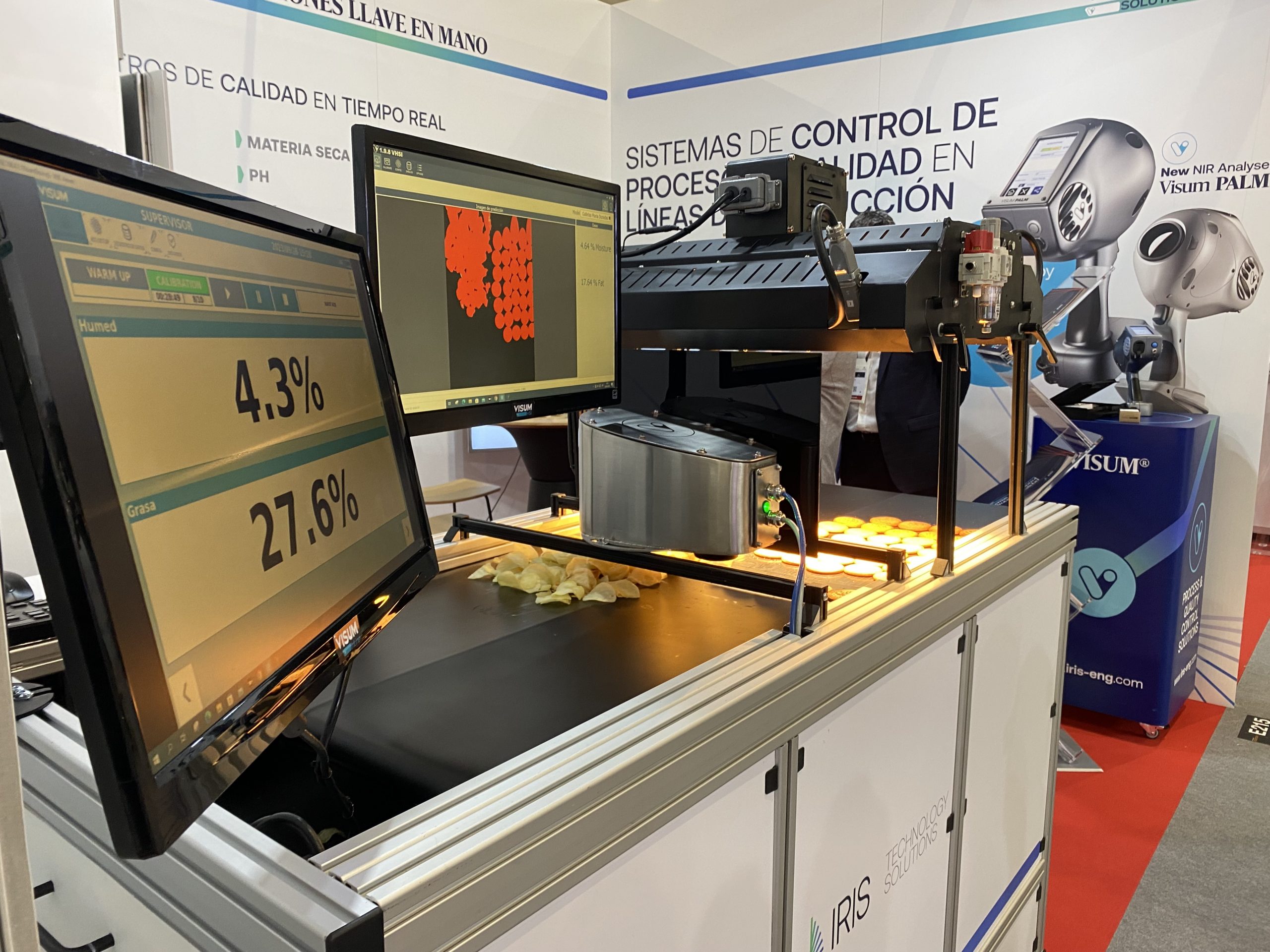

Plastic Analysis with NIR Visum Palm™: Precision, Agility and Versatility for Industry

Plastic Analysis with NIR Visum Palm™

The plastic analysis and classification have become more critical than ever—driven by new regulations and environmental practices—across various sectors, from material manufacturers and waste recovery operators to recyclers, scrap dealers, and companies processing recycled plastics.

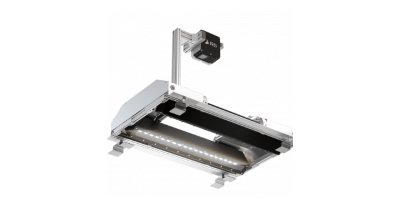

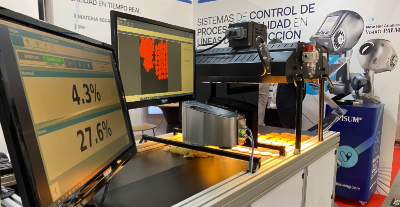

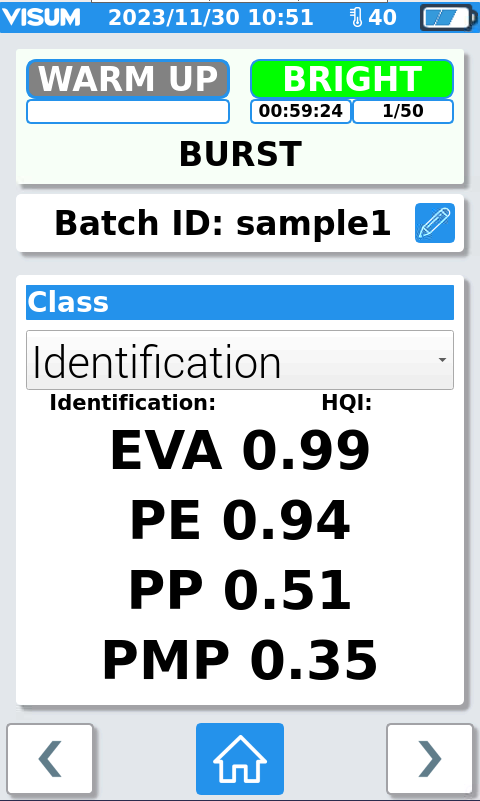

In this context, the portable NIR Visum Palm™ analyser stands out as an ideal tool for fast and accurate real-time plastic analysis identification, regardless of the sample type: waste, sheets, virgin or recycled pellets, flakes, and more. Visum Palm™ is a self-contained analyser, meaning it includes a built-in computer, software, and touchscreen, and does not require any connection to external devices such as a PC, tablet, or smartphone.

The device comes preloaded with a free plastic analysis identification library containing 39 classes, covering the most common polymers. It can be used as a handheld device for direct contact analysis or as a benchtop instrument in a laboratory or material reception area, with different sample holders available to suit various sampling needs and sample types.

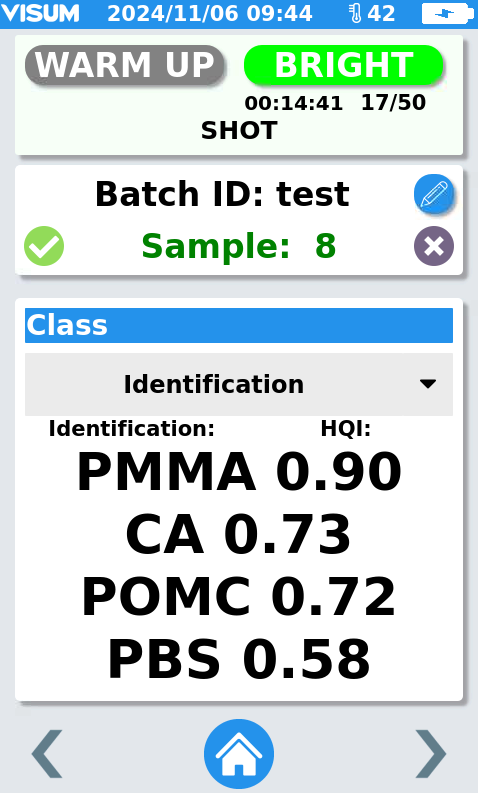

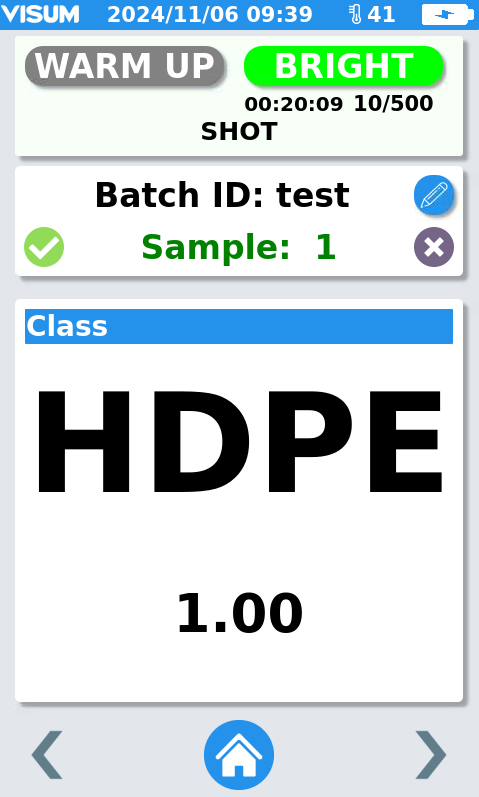

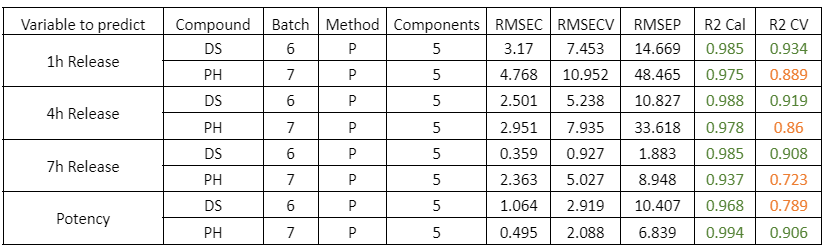

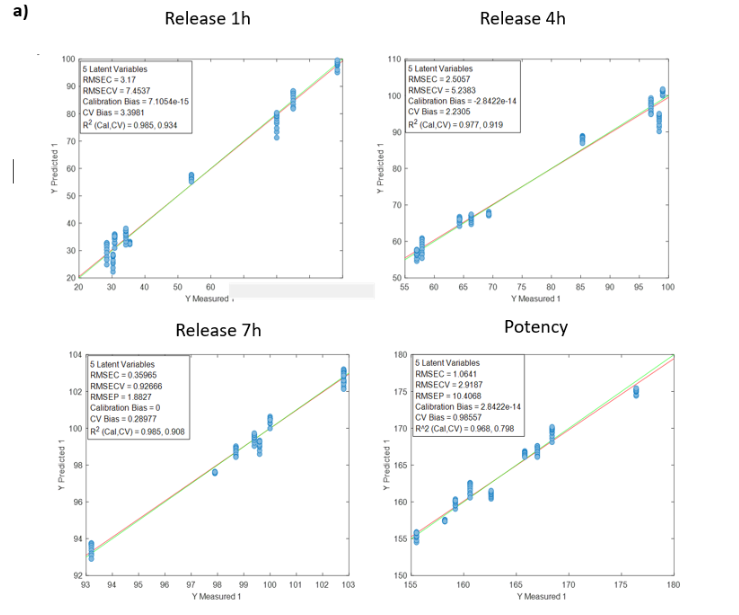

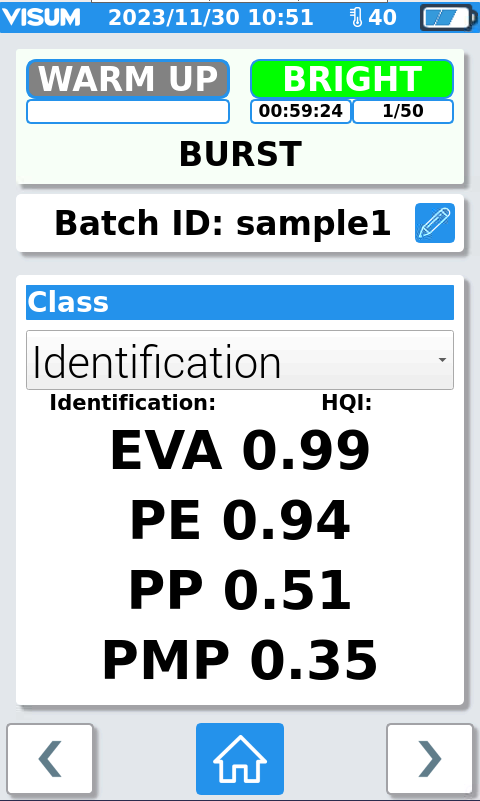

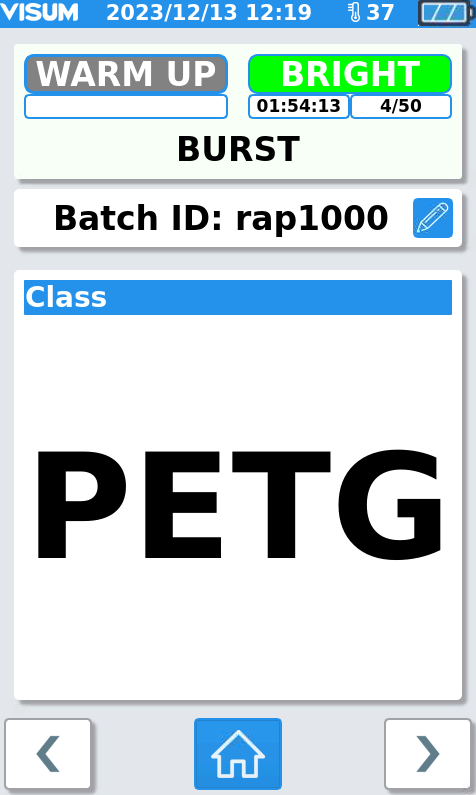

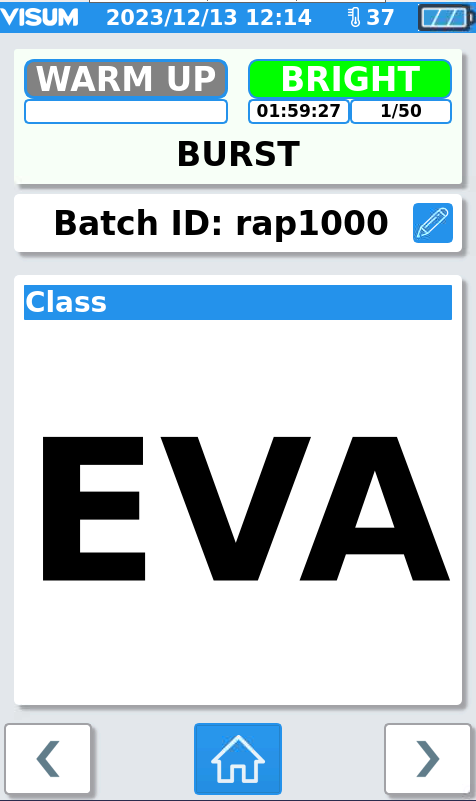

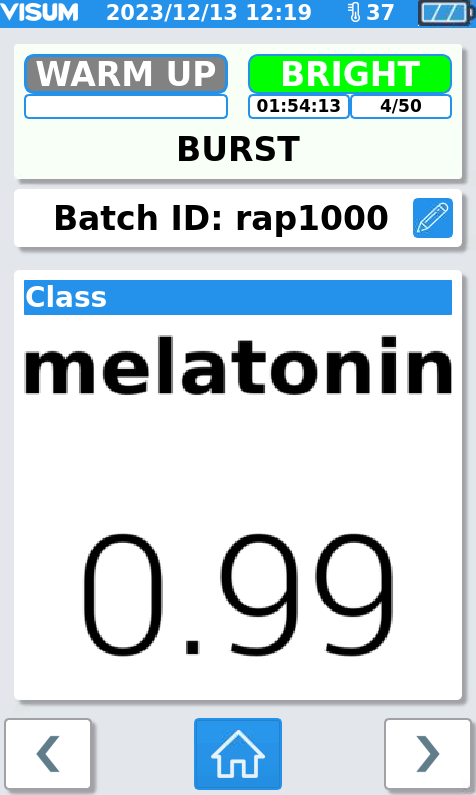

Plastic analysis mode: Identification (left) and classification (right)

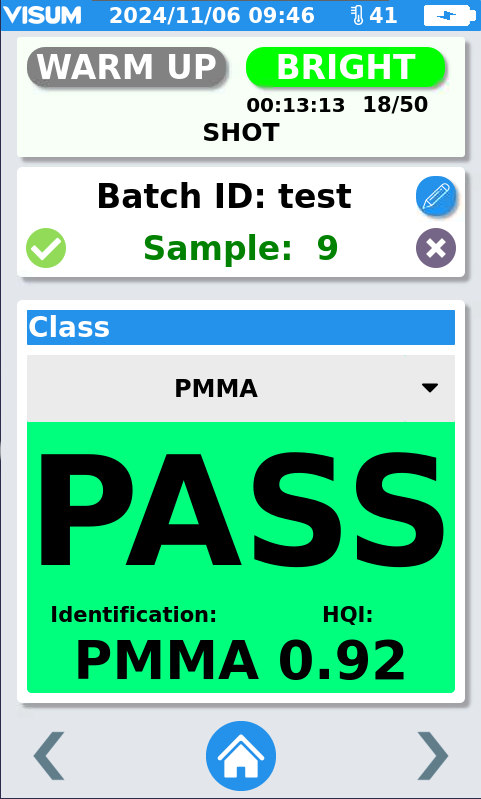

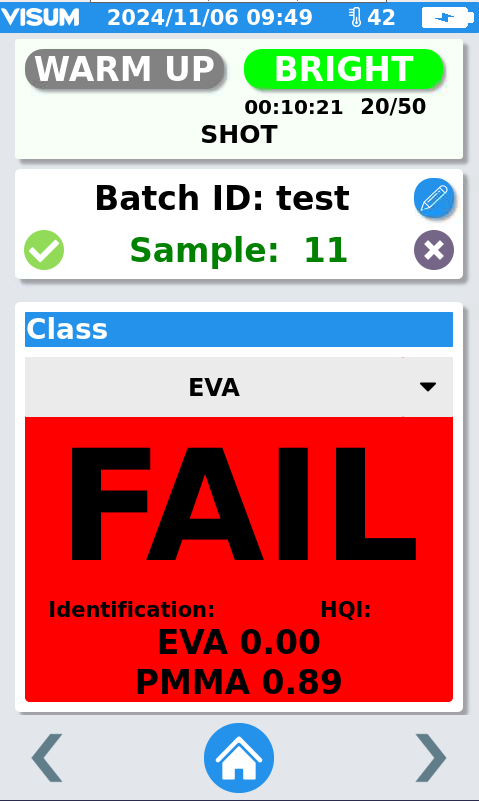

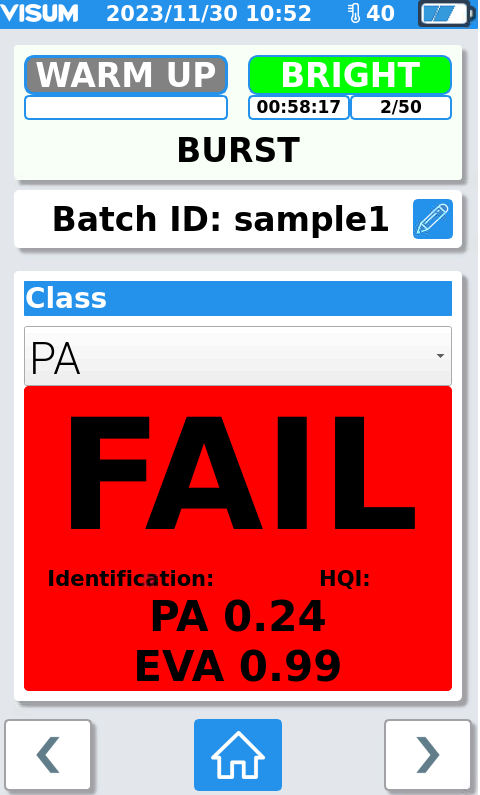

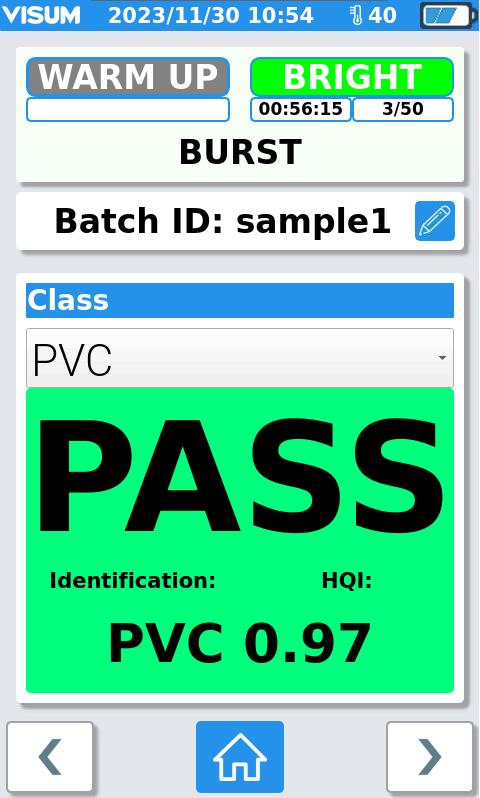

Plastic analysis mode: Verification (PASS/FAIL) and correct material.

What Plastics Can Visum Palm™ Identify—and What Are Its Limitations? | Plastic Analysis

As mentioned above, Visum Palm™ includes a library of 39 plastic classes, including:

PMMA, PE, PC, PETG, EVA, PVC, PET, PU, PS, ABS, PA, PP, VIN, PLA, PBT, PMP, POMC, PPS, PVA, PPSU, EMA, PHBV, PAEK, PBAT, PBS, TPES, TPS, MABS, HIPS, MBS, SBC, PCL, PEEK, PHB, SAN, PI, PB, HDPE, LDPE.

This library is periodically updated to ensure optimal coverage and performance in real-world applications.

The analyser is compatible with a wide range of sample types, including:

-

Post-consumer plastic waste: bags, bottles, jars, and various parts. In cases of surface dirt, minimal cleaning is recommended. Thanks to its spectral range of 900–1700 nm, a 10 mm measurement spot, and strong illumination, Visum Palm™ offers minimal penetration, making it less sensitive to dirt or coatings compared to extended-range instruments that only scan the surface.

-

Pellets (virgin or recycled): can be analysed in benchtop mode using dedicated sample holders.

-

Flakes: ideal for recycling lines where rapid polymer-type classification is essential.

-

Plastic parts of different sizes and geometries: sample shape can affect spectral quality, so extra care should be taken with curved or uneven parts to avoid anomalous readings.

-

Powders and liquids: can also be analysed, provided the appropriate sample holders are used—several are available.

Limitations of Plastic Analysis with Visum Palm™

Like any analytical technique, NIR spectroscopy has intrinsic limitations related to its physical detection principle and the 900–1700 nm spectral range used by Visum Palm™. In the following cases, plastic analysis may be unreliable or not possible:

-

Black plastics containing carbon black: this additive absorbs all NIR light, making this technique unsuitable.

-

Plastics requiring detection outside the spectral range: some polymers need broader spectral coverage for confident identification.

-

Microplastics and very small pieces (< 2 mm): the small size prevents effective spectrum capture.

NIR spectroscopy is an empirical technique: spectra must be interpreted and compared against a reference database. For this reason, individual evaluation is always advised for complex or similar samples.

In scenarios where material differences are minimal, Visum Palm™ allows for plastic analysis by creating specific classification models using advanced mathematical algorithms, improving accuracy through a second step of confirmatory analysis.

Create and Maintain Your Own Plastic Library - Plastic Analysis

Our field experience confirms that plastic sample variability is vast, whether by polymer type, shape, colour, coating, or origin (virgin, post-consumer, or recycled). Although the built-in library is regularly updated, covering all possible combinations is not feasible.

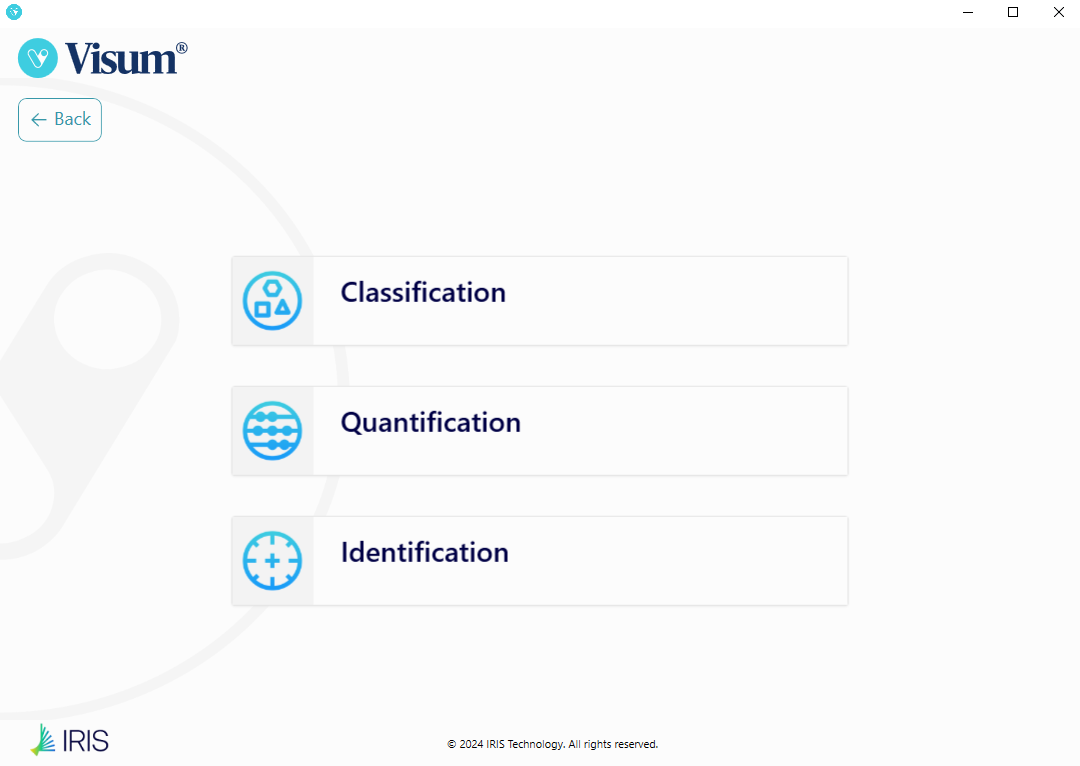

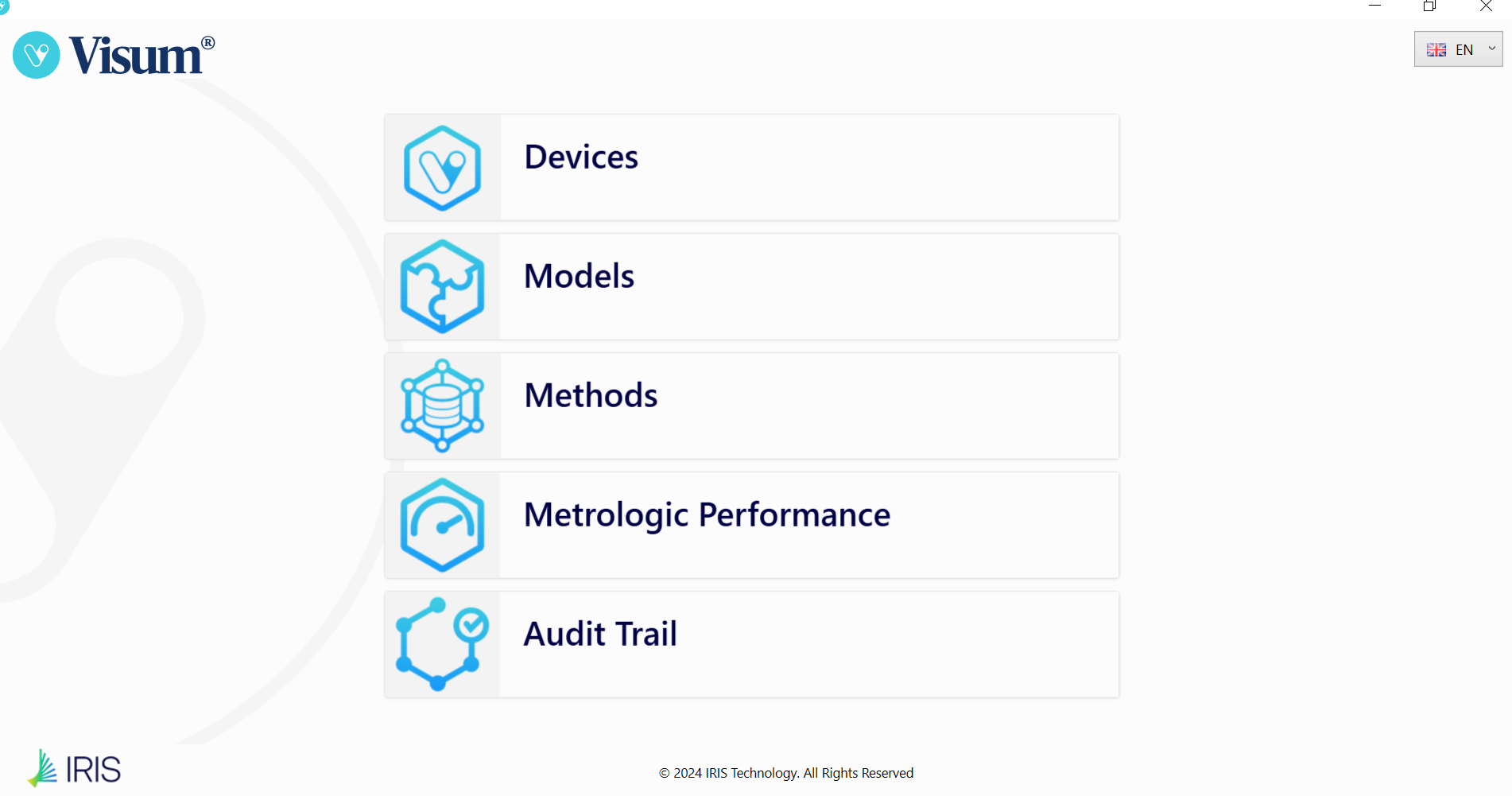

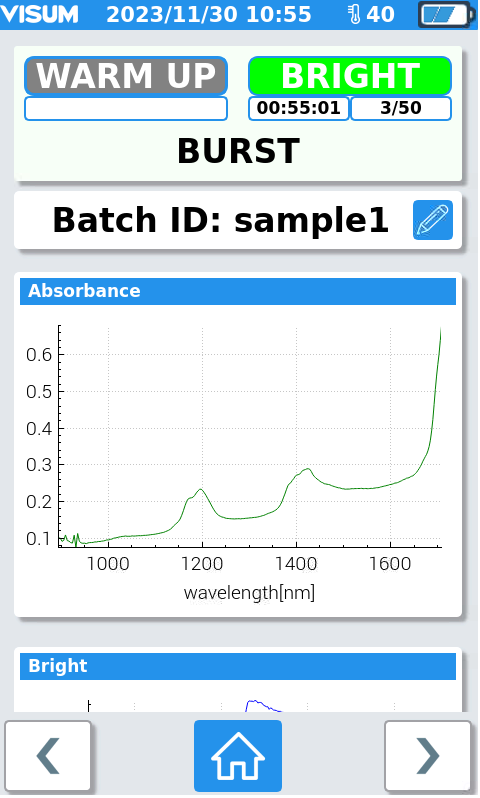

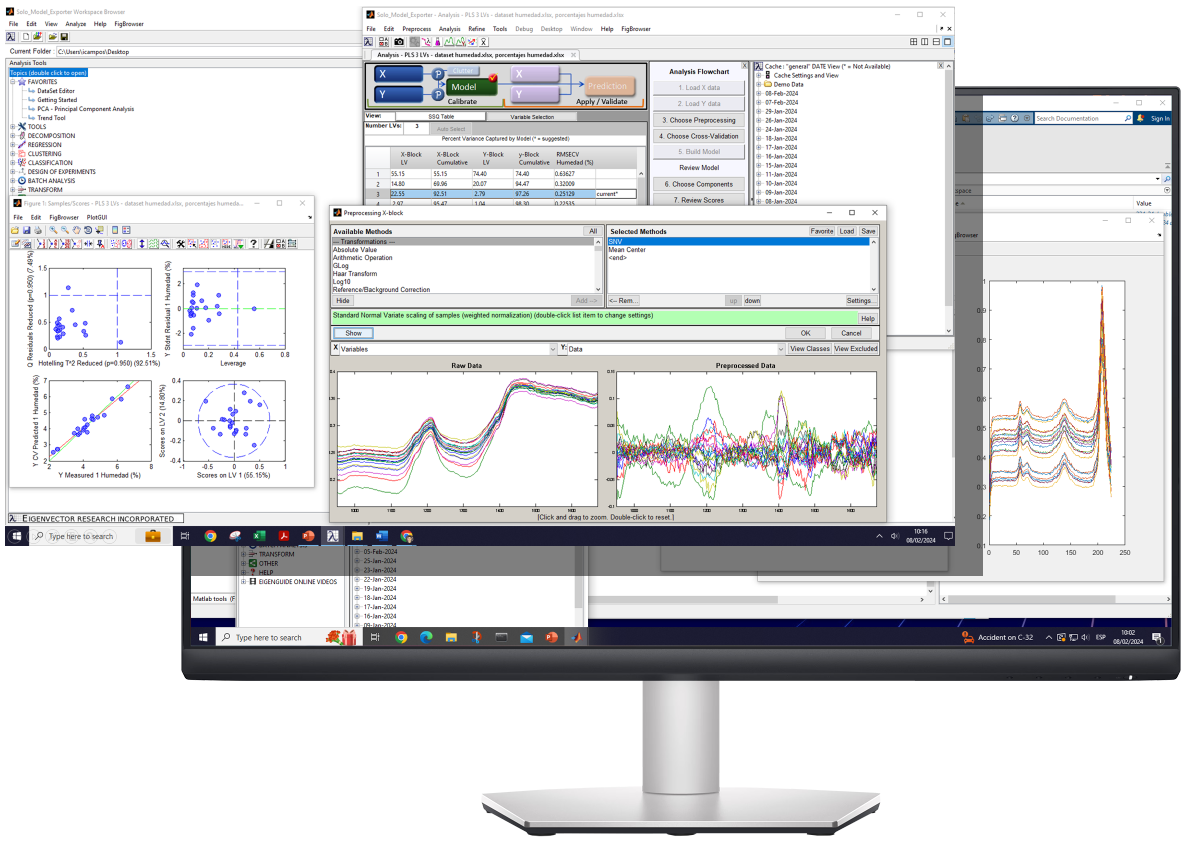

Therefore, each device comes with the Visum Master™ SMART PC software, allowing end users to:

-

Expand the existing library with their own samples.

-

Continuously update it without needing technical spectroscopy knowledge.

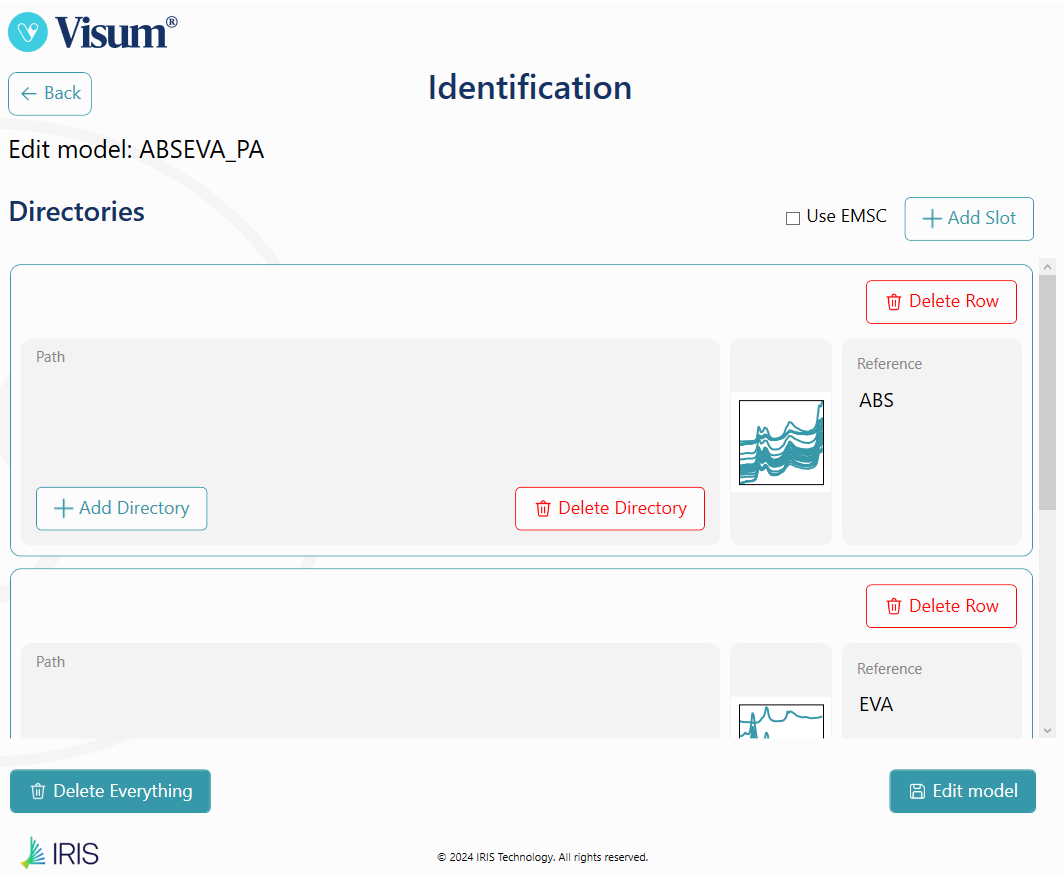

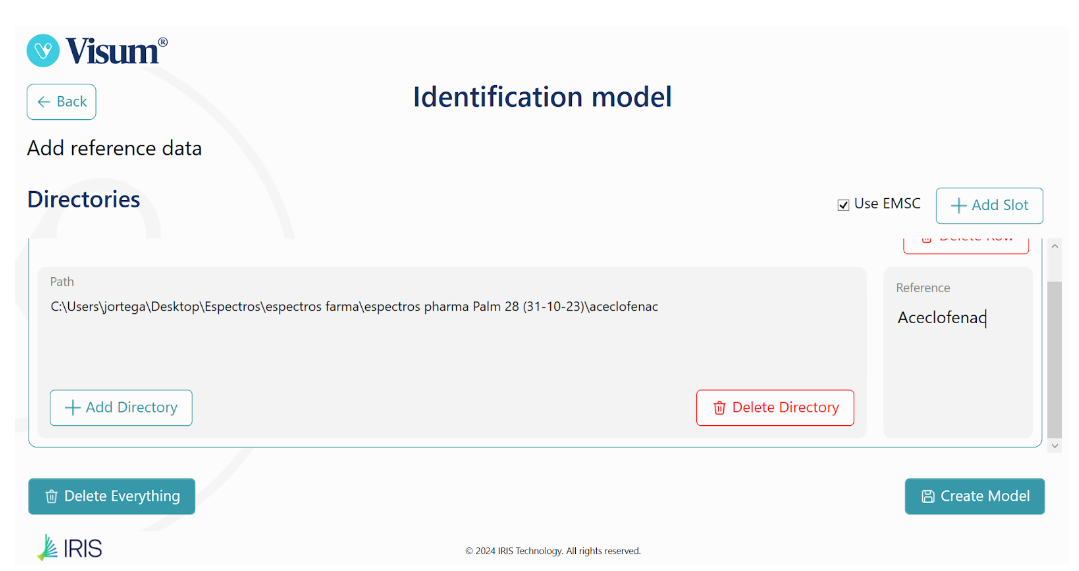

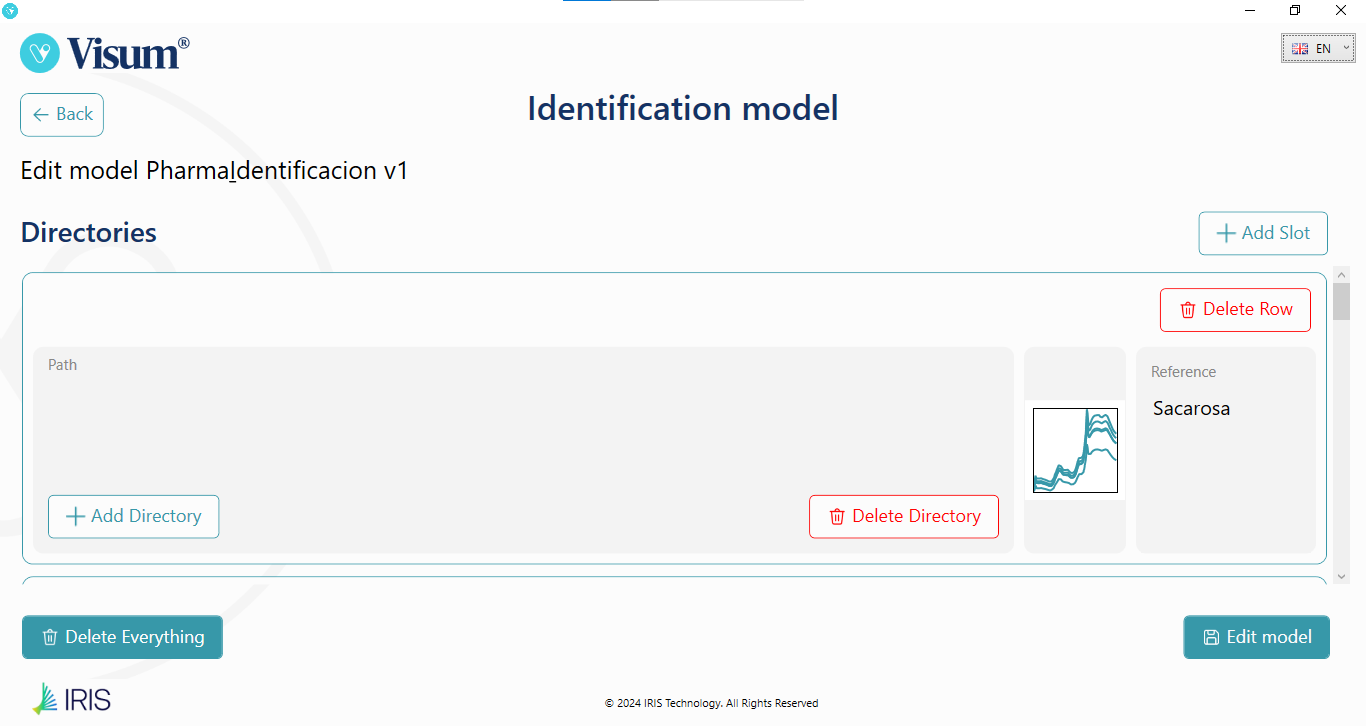

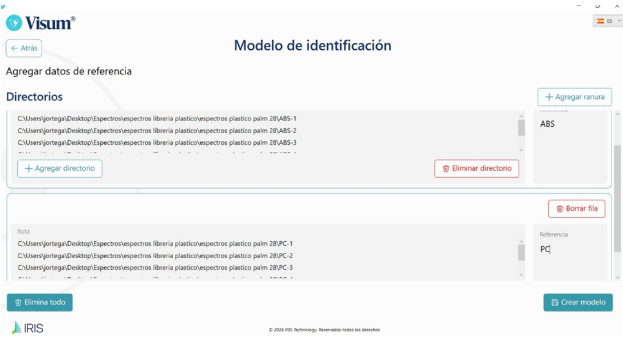

Below is an example of how a personalised library is created or updated, involving spectrum acquisition of different classes and variations in shape, colour, and surface characteristics—followed by assigning the correct material name.

Plastic analysis Visum Master™: Development or updating of an identification or classification library with Visum Master™ SMART.

This empowers recyclers and manufacturers to independently build a robust, up-to-date, and process-representative library tailored to their specific needs.

Conclusion

Visum Palm™ provides a practical, accurate, and versatile solution for plastic analysis, identification and classification in industrial environments. Its portability, ease of use, and compatibility with different sample types—from waste and pellets to flakes and parts—make it a valuable asset for both laboratories and production floors.

While NIR technology has certain limitations—particularly with black plastics, highly filled materials, or specific formulations—the ability to create custom libraries and classifications using Visum Master™ SMART makes this system adaptable to nearly any production context.

In a world where traceability and correct material sorting are increasingly critical, Visum Palm™ stands as a strategic tool for companies aiming to enhance their recycling processes, quality control, or fast polymer identification workflows.