Among the 60 million tonnes of plastic produced in Europe every year, only 30% of the total is recycled and the 79% of plastic waste has ended up in landfills or as litter in the natural environment. This is a fact that will produce an environmental disaster in a not too far future.

The European Commission has put in place some recent measures to help make plastic more sustainable. A plastics strategy adopted in 2018 aims to tackle the problem by transforming how plastic products are designed, used, and recycled. One key target is to recycle 55% of plastic packaging by 2030. Packaging, which is often made up of different types of plastic, making it challenging to recycle, has a high environmental footprint: about 40% of plastic produced is used for packaging, which is typically discarded after use.

As part of the MultiCycle project, Dr. Elodie Bugnicourt, Project Manager, H2020 and Innovation Unit leader at IRIS, and her project partners are aiming to scale up a patented process called CreaSolv developed by the Fraunhofer Institute in Munich, Germany which can give multilayer packaging and fiber-reinforced composites a second life again and again.

With the CreaSolv process, recycled plastic is of high quality and the process is more efficient. It can recover a polymer instead of a monomer which is an advantage because it is not necessary to use energy to polymerize the material again.

After several small scale trials with multilayer packaging and composites, CreaSolv goes a step beyond, the design of a large-scale pilot plant in Bavaria where trials should start in July.

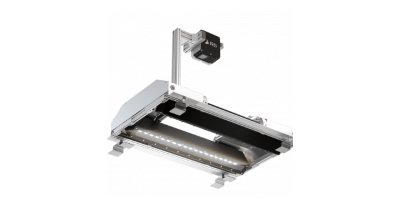

Real-time monitoring of biofuels with NIR spectroscopy

Real-time monitoring of biofuels with NIR spectroscopy

Hyperspectral NIR: Applications in the Food Industry

Hyperspectral NIR: Applications in the Food Industry