NIRS analysis of Brix degrees in whole apples in real time

NIRS analysis of Brix degrees in whole apples in real time

Real-time cooking degree monitoring of gummies with Visum Raman In-Line™

Real-time cooking degree monitoring of gummies with Visum Raman In-Line™

Water Activity Analysis in animal feed with Visum Palm™ portable NIR

Water Activity Analysis in animal feed with Visum Palm™ portable NIR

The water content in animal feed is a critical factor in feed quality and safety. Water is not only essential for the biological functions of animals, but also plays a crucial role in feed stability during storage, preservation, microbial activity, and food safety. Moisture, or more specifically water activity (Aw), directly influences the stability of the product and the likelihood of reactions affecting its quality.

In this paper we present the analysis of water content in animal feed by real-time infrared spectroscopy with the Visum Palm™ handheld analyser property of IRIS Technology Solutions SL.

Water Activity Analysis in animal feed

Water activity (Aw) is a more accurate measure than moisture content for predicting microbiological stability and feed shelf life. Water activity is defined as the ratio of the vapour pressure of water in the feed to the vapour pressure of pure water at the same temperature. It is expressed on a scale from 0 to 1, where 1 indicates the presence of pure water.

In animal feeds, the typical Aw value is typically in the range of 0.2 to 0.7 for dry products, which allows for greater stability during storage. When the water activity is higher than 0.7, the growth of microorganisms such as moulds and pathogenic bacteria is facilitated.

Thus, keeping water activity below 0.70 is crucial to prevent microbial growth and ensure feed safety.

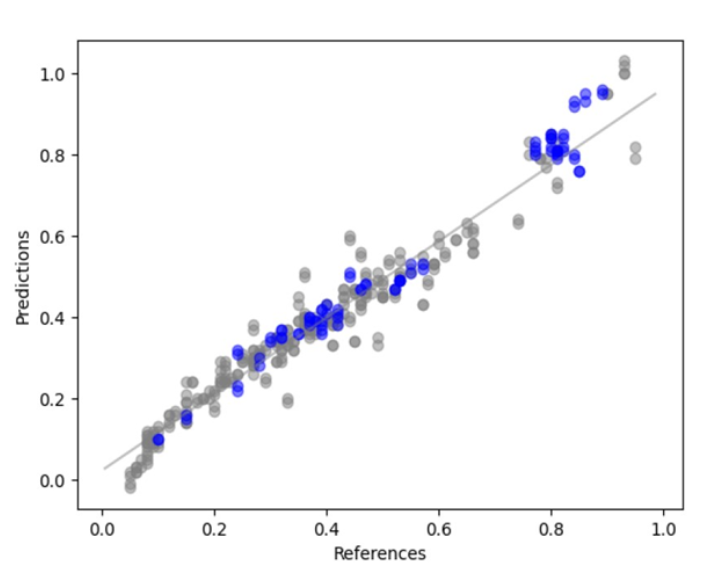

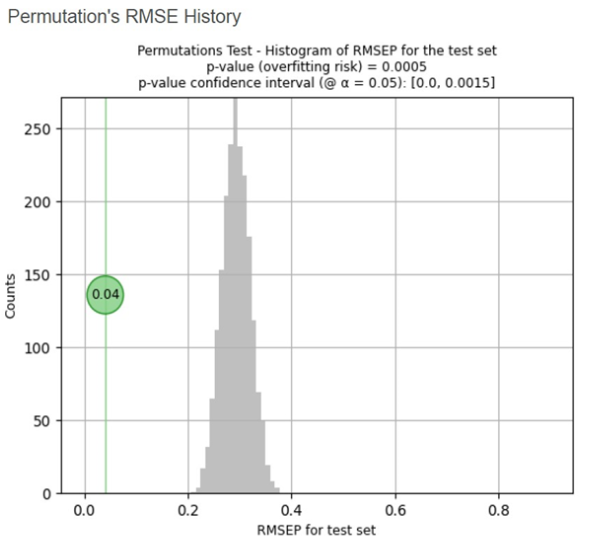

Left: Resultant regression curve for Aw – calibration samples (grey) and validation samples (blue) Right: Fisher-Pitman permutation test to determine the risk of overfitting the Aw model.

Traditional Analysis Method

The most common traditional method in the industry for measuring the water content in animal feed is oven drying. This procedure involves the following steps:

- Feed sample: A specified amount of sample is extracted and weighed.

- Drying: The sample is placed in an oven at a constant temperature (usually between 105°C and 110°C) for a certain period of time (usually between 2 and 4 hours).

- Calculation of water content: At the end of drying, the sample is reweighed and the weight loss is calculated as the amount of water evaporated.

This method is widely used due to its accuracy and simplicity, although it is time-consuming, labour-intensive in terms of sampling.

Determination of water activity with NIRS in seconds

For the development of the predictive model for water activity determination, we worked closely with a Mexican pet food manufacturer. A total of 345 calibration samples in the 0.1 – 1 % Aw range were used, of which 20% were automatically separated by the Model Builder Visum Master™ software for internal validation of the NIRS method.

As the processing of the data (spectra and laboratory references) is fully automated, the software itself executes and applies the most convenient processing routine and parameterisations according to the input data. At the end, it automatically applies a permutation test to check that the resulting model is useful for analysing future samples and that it is not the product of overfitting, which is also known as overfitting risk, an indicator of confidence in the analytical method.

As a result, the model developed to predict water activity in animal feed yielded a correlation coefficient (R²) of 0.96 and an RMSEP (root mean squared error of prediction) of ± 0.04. This validates the use of the Visum Palm™ portable NIR analyser as a real-time (< 3 seconds) method to determine water activity in feed and animal feed as a much more efficient alternative to the traditional method.

Importance of Water Content Analysis for Food Safety

Controlling water content and water activity in animal feed is essential for food safety for several reasons:

- Prevention of microbial growth: Microorganisms need free water to grow and reproduce. If moisture content and Aw are too high, this facilitates the growth of pathogens such as Salmonella, E. coli and moulds, which can cause disease in both animals and humans, as they are linked to the food chain.

- Product preservation: A feed with controlled water activity has a longer shelf life. Microbial growth and chemical reactions that cause nutrient deterioration are minimised when Aw is in optimal ranges.

- Toxin control: Poor management of water content can allow the appearance of fungal toxins, such as aflatoxins, which can be highly hazardous to animals and thus to the human food chain.

- Maintenance of nutritional quality: An adequate moisture level ensures that the nutrients present in the feed remain stable. Fat oxidation and vitamin degradation are accelerated in high moisture conditions, which reduces the nutritional quality of the feed.

- Costs and efficiency: Controlled water content reduces economic losses, as the feed will have better stability during transport and storage, reducing the risk of losses due to contamination or spoilage.

Conclusions of analysis of water activity in animal feed

Visum Palm™ handheld or laboratory analyser

Controlling water content and water activity in animal feed is vital not only to maintain the nutritional quality of the feed, but also to ensure food safety and prevent risks associated with microbial growth and contamination.

Traditional methods of analysis such as oven drying provide essential tools to keep these factors under control but are resource and time intensive compared to water activity analysis using NIRS infrared spectroscopy.

The portable Visum Palm™ analyser is capable of predicting Aw in feed samples in less than 3 seconds with an accuracy of ± 0.04, contributing to proper management of water activity during the production process, which is key to ensuring feed quality, animal health and sustainability of food production. As a handheld or benchtop (laboratory) multiparametric analyser, it can be used simultaneously to determine moisture, fat and fibre content, to mention the most important parameters in the production of pet food, thus constituting a fundamental tool for efficient analytical and product controls, even for agri-food raw materials.