Water Activity Analysis in animal feed with Visum Palm™ portable NIR

Water Activity Analysis in animal feed with Visum Palm™ portable NIR

European Commission Highlights IRIS Technology Solutions for its Innovative Role in the AIDPATH Decentralized Advanced Therapy Production Project

European Commission Highlights IRIS Technology Solutions for its Innovative Role in the AIDPATH Decentralized Advanced Therapy Production Project

Real-time cooking degree monitoring of gummies with Visum Raman In-Line™

Real-time cooking degree monitoring of gummies with Visum Raman In-Line™

Jelly sweets, also called jelly candies, jelly beans, jelly fruit candies or gummies, are a broad category of chewy jelly-based candies that have been popular around the world for more than a century and more recently also include vitamins in their recipes for the production of healthy candies.

Depending on the recipe, gummies are made from starch, pectin, gelatin, glucose syrup, sugar, water, sodium citrate, fruit and plant extracts, flavourings, colourings and other additives, all of these ingredients are mixed together and various characteristics are controlled to obtain the best taste and texture. In order to meet these requirements, a critical factor during the production of gummy dough is the degree of starch gelatinisation and therefore a critical factor is to analyse the residual starch after the cooking process.

Level of starch cooking: the gelatinisation process

To achieve the gelatinisation of the gummy mass, starch is often used, of which potato and corn starch are the most popular and are available in a width range of modifications.

Gelatinisation, or ‘cooking’, is the process by which the starch granules are subjected to the action of water and temperature, which breaks the hydrogen bonds and dissolves the granules into the candy mass. After being subjected to a subsequent depositing and drying process, the final texture and consistency of the gummy is obtained.

In the confectionery industry, gelatinisation usually takes place in continuous cooking systems

Traditional analysis

At present, there is no inline method to monitor the degree of cooking continuously during production. Although there are several methods to determine the degree of cooking, they are all based on taking samples and analysing them off-line. This technique is labor intensive and requires qualified personnel, in addition to the difficulty it poses to make decisions and be able to correct process parameters in real time and thus avoid soft gummies, with an incorrect texture or subsequent problems in the demoulding process.

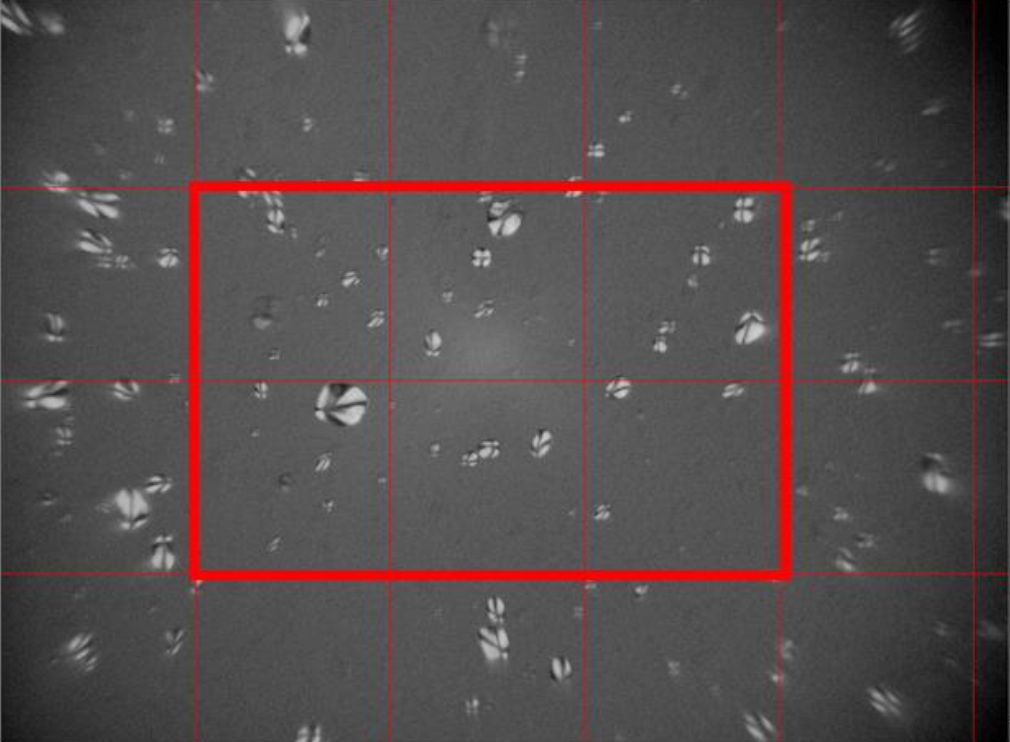

One of the methods used to control the end point of the cooking process is carried out in the laboratory using the technique of counting starch granules with a polarised light microscope.

This technique consists of the visual counting of starch particles and, depending on the quantity of particles present in the sample, the analyst can determine whether the cooking has been satisfactory or whether it is necessary to modify process parameters (temperature) or extend the cooking time. If the number of starch granules in the sample is less than or equal to 10, the degree of cooking is considered to be adequate, whereas if the number is higher, the degree of cooking is considered to be insufficient.

Starch granules under the polarised light microscope with the area marked in red for counting.

A partnership for the future of the industry

IRIS Technology Solutions SL, a leading Spanish manufacturer of spectroscopy-based solutions for the control and monitoring of industrial processes, in collaboration with the Dutch manufacturer Tanis Confectionery B.V., a worldwide manufacturer of machinery for the production of gummies, have teamed up to develop a real-time method for monitoring the starch gelatinisation and thus offer an alternative, value-added solution to the entire industry.

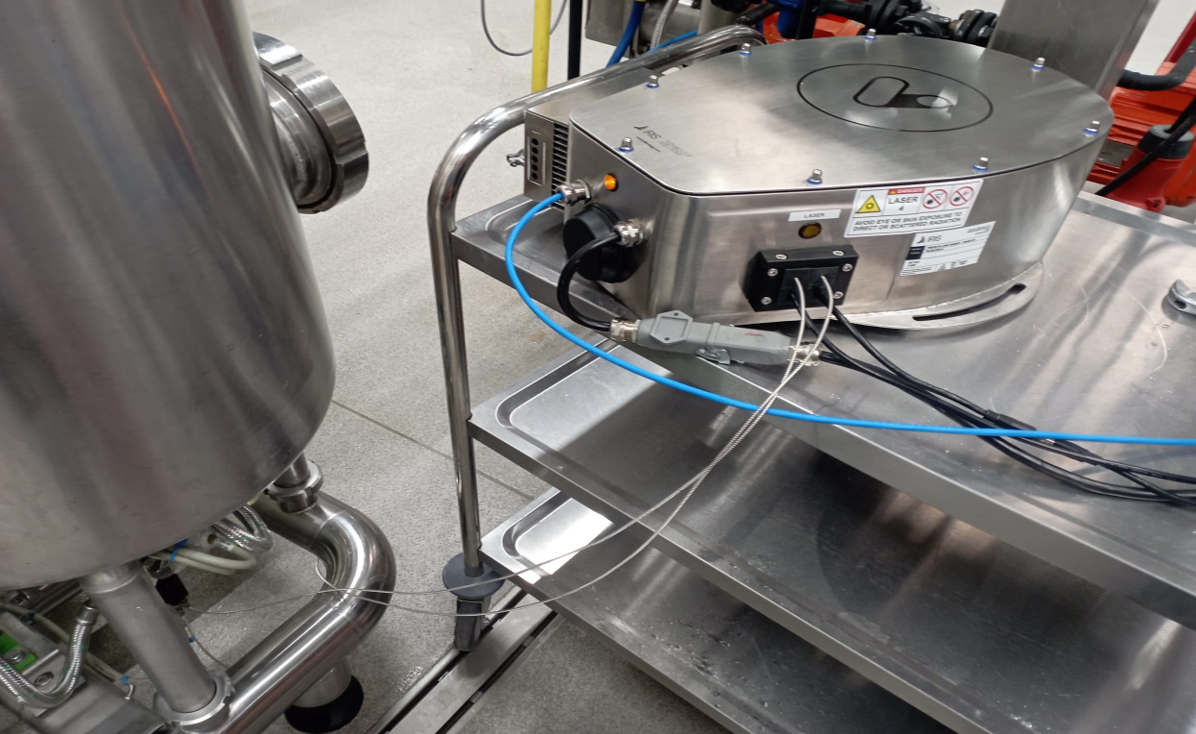

Within this framework of collaboration, tests have been carried out for months in the facilities of the Tanis Innovation Center (The Netherlands) using the Visum Raman In-Line™ analyser property of IRIS Technology Solutions SL.

Raman spectroscopy is an analytical technique used to observe vibrational, rotational and other low-frequency modes in a system. It relies on the inelastic scattering of monochromatic light, a laser, to provide detailed information on molecular vibrations and chemical composition. Unlike NIR spectroscopy, it is particularly suitable for monitoring aqueous matrices or for determining the concentration of an analyte dissolved in water.

This technology is a non-invasive analytical technique that analyses in real time the product flow, in this case the gummy dough, by inserting a food grade immersion probe, capable of providing real time results of what is happening in the process with the appropriate calibration

Developing a real-time analytical method

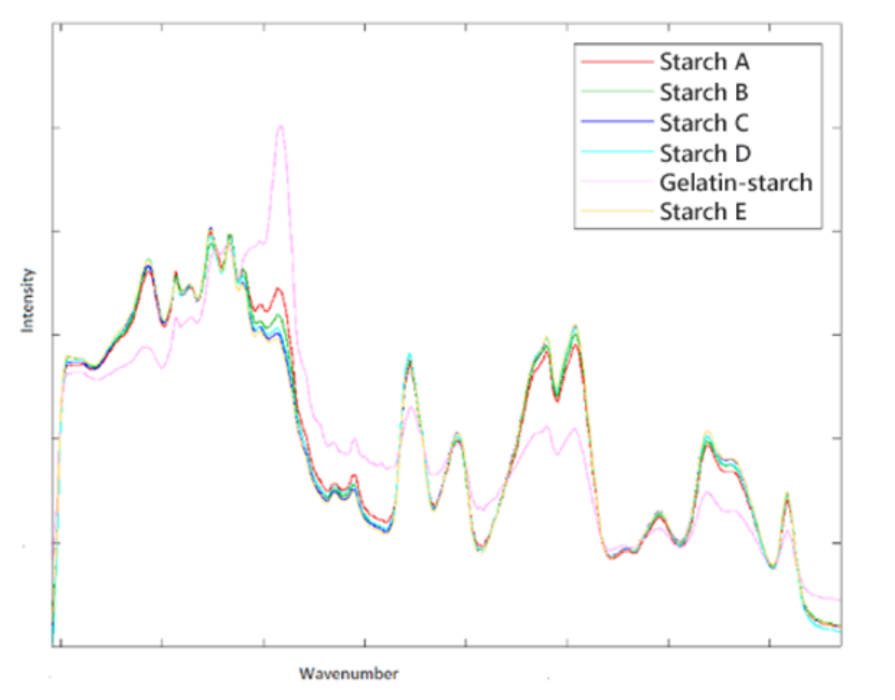

During the test phase, different recipes based on potato starch, corn starch and with a combination of gelatin with starch were manufactured and monitored and cooked at different temperatures to obtain different degrees of starch gelatinisation during the cooking process in order to develop the cooking level prediction algorithm (adequately cooked / undercooked).

While the Visum Raman In-Line™ analyser was acquiring spectra throughout the cooking process of the different batches or recipes, samples were extracted and analysed by the reference method of visual counting using polarised light microscopy.

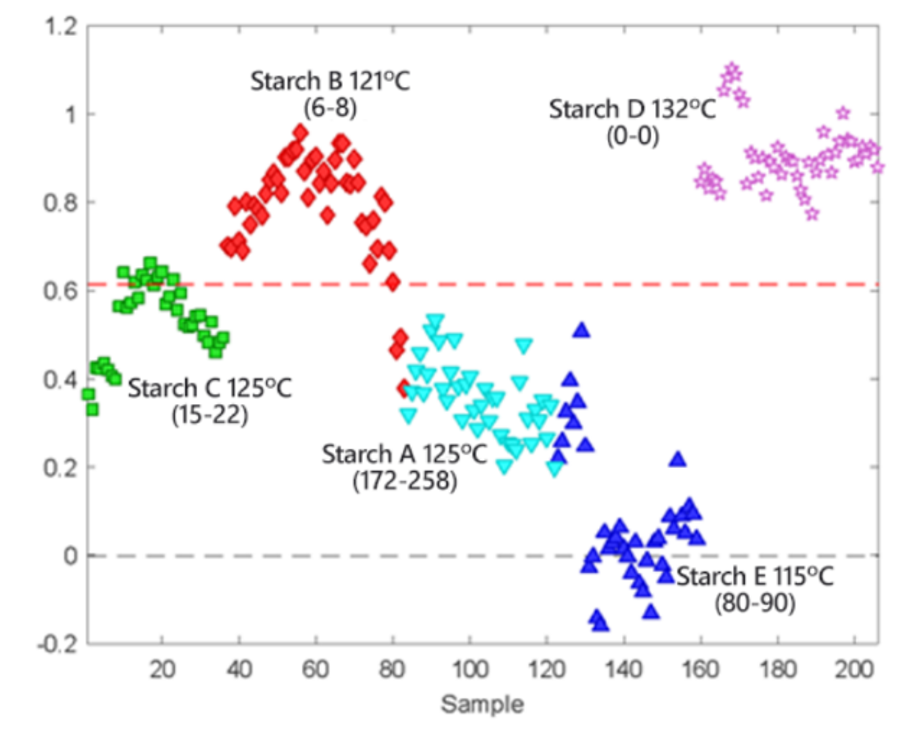

For the monitoring of the continuous process, the model was developed to determine two final classifications, “Adequately cooked” (≤10 starch granules) and “Undercooked” (>10 starch granules). The result obtained is the outcome of 3 consecutive analyses to confirm the degree of gelatinisation and to avoid any misclassification.

Left: comparison of the average pre-processed Raman spectrum of the different recipes used. Right: classification results of the model for five of the recipes. The points above the red dotted line correspond to measurements classified as adequately cooked.

Conclusions

From the tests carried out, it could be concluded that the same predictive model can be used to make cooking level predictions for both corn and potato starch-based recipes.

For all batches made from both potato and corn starch the Visum Raman In-Line™ correctly classified their cooking level.

Next to the developed models it is possible to create unique models for unique candy recipes and ingredients with this inline method.

For the recipes with gelatin or modified starch that were analysed, more significant spectral differences were observed, so specific classificatory predictive models were performed for these formulations with similar validation results.

It is therefore possible to successfully predict the cooking level of both corn and potato starch-based jelly bean dough as well as different modified gelatines with the real-time raman process analyser, a truly more efficient alternative to the traditional and current method of analysis.

Key features of the Visum Raman In-Line™ Process Analyser

- Sensor ready for use after switch-on (no warm-up required).

- Analyser designed to operate in industrial environments.

- Computer and embedded operating system.

- 785 nm laser excitation source.

- Internal cooling system stable at -40°C.

- IP 65-68.

- Connection to the process via a food grade immersion probe.

- Compatible with different communication drivers with PLC or SCADA of the plant.

- It can be easily integrated in any position of the pipe.

- Low-maintenance device.

- With the Visum Master™ SMART version software, the user has an AI-supported Model Builder for developing, adjusting or updating predictive models for different recipes or formulations.

Visum Raman In-Line™ process analyser