RESCHAPE PROJECT: RESHAPING SUPPLY CHAINS FOR POSITIVE SOCIAL IMPACT

RESCHAPE PROJECT: RESHAPING SUPPLY CHAINS FOR POSITIVE SOCIAL IMPACT

Plastic identification, verification and classification using Visum Palm™

Plastic identification, verification and classification using Visum Palm™

Real-time NIR grain analysis

Near infrared spectroscopy (NIR) is a valuable analytical tool for real-time analysis of the chemical composition of a wide variety of products, including those of agricultural origin. In this article, we will address the application of NIR technology for grain analysis and in particular of two varieties of wheat grains: soft (Triticum aestivum) and hard (Triticum durum), as well as yellow corn (Zea Mays).

Grain analysis with continuous or portable NIR technology

The quality of food products depends directly on the quality of the raw materials used. Therefore, assessing their composition, purity and physicochemical characteristics is of interest to the food industry.

In grain analysis, NIR spectroscopy plays a crucial role in providing detailed information on several parameters simultaneously, with moisture being one of the critical factors in assessing grain quality. However, this technique also makes it possible to analyse other key parameters such as protein, fat, fibre, ash and starch content, thus offering a more rigorous control according to established quality criteria.

NIR spectroscopy differs from other techniques in that it is non-destructive, which means that measurements can be made continuously without compromising the integrity of the batch or sample under analysis. In addition, results are obtained in a matter of seconds, streamlining grain analysis, quality control processes and allowing instant decision making compared to conventional wet chemistry analysis.

Below we will look at two ways of performing NIR grain analysis, either fully automated and continuous on the production line or by means of a portable analyser, useful for analysis in the field, in the raw material reception warehouse or in discontinuous processes.

Continuous and real-time grain analysis: wheat and corn grains

A Visum NIR In-Line™ (900-1700 nm) continuous analyser was used to develop the grain calibration model and 30 calibration samples and 7 validation samples were used from each class. In addition, duplicate reference analyses were obtained from each sample to mitigate the inherent error in the primary method of analysis. For moisture analysis, a thermogravimetric moisture meter HE53 (Metler Toledo) was used, protein was determined by the Kjeldahl method and fat content was determined by the Soxhlet method.

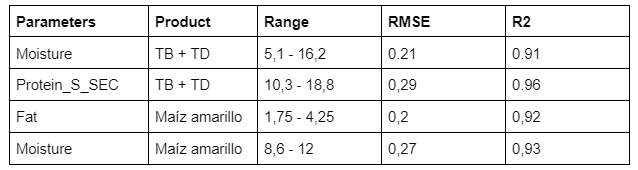

The table below shows the main results and figures of merit of the soft grain (TB) and durum grain (TD) wheat for the parameters moisture and protein expressed as % dry matter. In addition, the results for fat and moisture of yellow corn are also shown. It is important to clarify that the same calibration is useful and groups both wheat classes into a single family or method of analysis. No significant spectral differences were observed for their individual treatment.

* Table 1: Analysis of common wheat, durum wheat and yellow corn. Main figures of merit resulting from the Visum NIR In-Line™ continuous analyser.

Grain analysis with NIR spectroscopy is also important in animal feed manufacturing to optimise diets and yield. In the agri-food sector, the NIR technique offers numerous advantages over wet chemistry methods, mainly due to the immediacy of the result and the possibility of being able to make technological decisions on the spot, even more so if we consider the introduction of these systems such as the Visum NIR In-Line™ analyser in production lines that allow continuous monitoring of the entire product flow to ensure the ideal conditions of the process and the product, mitigating any deviation with phytosanitary consequences that may affect the safety of an entire batch, as far as moisture is concerned.

A portable NIR alternative for grain analysis

On many occasions, mainly due to the conditions and environment where grain analysis is to be performed, it can be of great use to work with a portable NIR grain analyser such as the Visum Palm™. This device, which works in the same spectral range (900 – 1700 nm) as the continuous analyser we saw earlier, is capable of determining in less than 3 seconds different parameters of interest in all types of grains, cereals and oilseeds.

Some of its main advantages, especially for field grain analysis, are:

- It is a self-contained analyser (embedded computer and touch screen). It does not need to be connected to any external device, tablet or smartphone to operate.

- It has a sample measurement area of 10 mm in diameter and illumination of 50 mm in diameter, which allows mitigating the heterogeneities present and obtaining more chemical information from each sample.

- Unlike most portable NIR grain analysers on the market today, it has a spectral resolution of 3 nm or 256 pixels, i.e. two to three times higher, allowing spectra, and therefore results, of high reliability and quality to be obtained.

- It includes factory libraries for different grain types.

- And it is supported by external Visum Master™ PC software, so that the end user can develop their own NIR calibrations and extend them in an automated, AI-assisted way. In this way, the user is not dependent on third-party libraries and has full autonomy to strengthen and extend his calibrations for new parameters or products according to his current or future needs.

We hope you found this article on grain analysis with NIR technology useful. For further information, we invite you to contact us by email at info@iris-eng.com.