Real-time NIR grain analysis

Real-time NIR grain analysis

IRIS Technology: Leading the Way in Material Detection with Hyperspectral Imaging for RECLAIM project

IRIS Technology: Leading the Way in Material Detection with Hyperspectral Imaging for RECLAIM project

Raw material analysis: identification (RMID), verification and classification

Raw material analysis with Visum Palm Gxp™

Raw material analysis identification (RMID) is a critical process in the pharmaceutical industry because it ensures the identity and quality of all materials and substances to be used in the production process. A practical and efficient way to be able to analyse and confirm the identity of all substances is by using a Visum Palm GxP™ portable NIR analyzer, being able to perform the analysis directly in the warehouse and obtain results in less than 3 seconds, thus avoiding laboratory overload and reducing cycle times.

No single technology provides a universal solution for the manufacturer’s entire list of materials.

While NIR is particularly effective for identifying primarily organic compounds, it can also be applied to certain inorganics under specific conditions, such as when they are hygroscopic, associated with water molecules (hydrates), or dissolved in an aqueous solution.

On the other hand, Raman spectroscopy has notable limitations with:

- Organic compounds that exhibit fluorescence (such as dyes and certain APIs).

- Substances with inherently weak Raman signals.

- Pure ionic inorganic compounds, such as NaCl, KCl, and HCl.

Why Visum Palm GxP™ in raw material analysis?

- It is a self-contained analyser and does not need to be connected or linked to any external device (smartphone, tablet or PC).

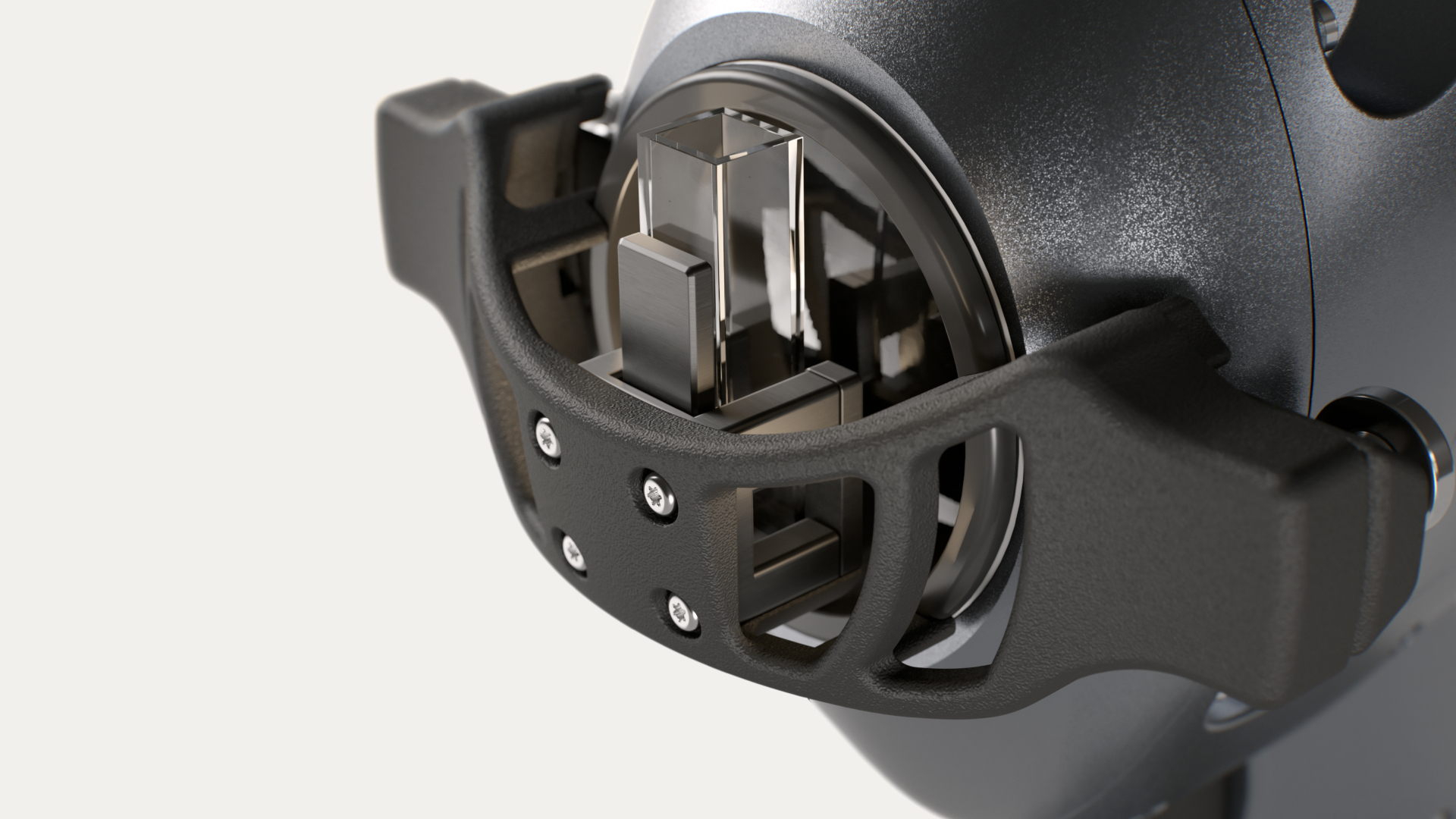

- It has double-functionality as a hand-held and benchtop device.

- It is useful for identification and also for quantitative methods.

- The sample measurement area is 10 mm and the illumination area is 50 mm. This allows to acquire more chemical information and to mitigate heterogeneities.

- It has a spectral resolution of 5 nm and 256 pixels, providing the highest spectral resolution across the entire range of portable analysers.

Figure 1: Benchtop mode with Visum Palm GxP™, allows the attachment of sample holders for powders, solids and liquids.

- CFR and GMP full compliance:

-

- Defined user roles for Analyst, Supervisor, and User Manager, with unlimited users.

- Password expiration settings configurable according to security policies.

- Audit Trail records stored in an encrypted binary file, along with a Results Audit Trail.

- Two-level electronic signature system (Analyst and Supervisor).

- Date and time settings aligned with CFR requirements.

- Secure system backup and restoration processes.

- IQ & OQ protocols in compliance with USP <1119>, PE 2.2.40, GMP, and GAMP 5 standards.

Analysis Modes with Visum Palm GxP™

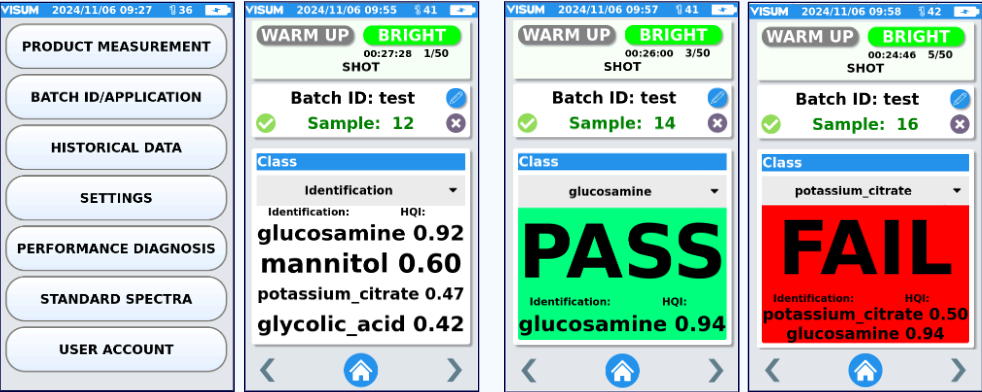

The Visum Palm GxP™ analyzer enables fast identification or verification of various solid, granulated, powdered, or liquid compounds in just seconds. It works by comparing the acquired spectrum with the reference spectrum of substances stored in its library. This comparison is based on a mathematical similarity index (HQI), which translates spectral differences into a numerical value.

As a result, the analyzer provides the most similar class or substance (see Figure 3), followed by a ranked list of other possible matches, ordered from highest to lowest similarity.

Unlike raw material analysis identification, which is agnostic to the material, the verification mode (see Figure 4) allows the analyst to select a specific substance from the library to confirm its identity. The result is presented as PASS or FAIL. In the case of FAIL, the system also suggests the most similar substance identified during the analysis.

Main screens Visum Palm™

Figure 2: Main Menu Figure 3: Identification analysis Figure 4: Verification analysis, PASS and FAIL with confirmation of correct substance.

Classification analysis - Raw material analysis

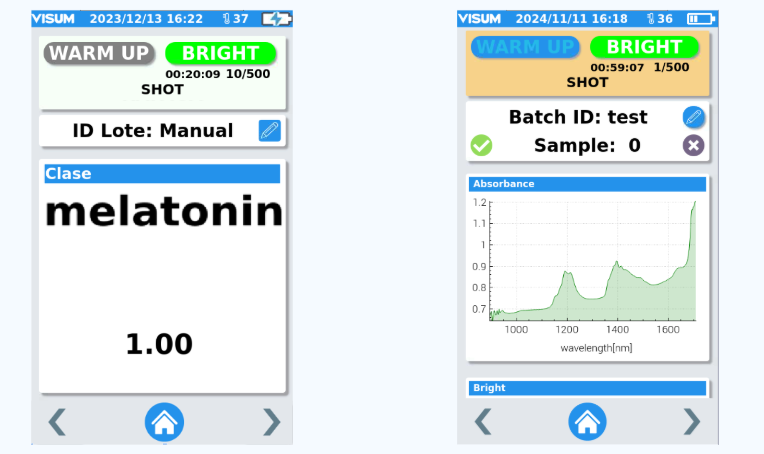

In contrast to the above, raw material analysis classification (Figure 5) is a function that allows to properly distinguish (classify) very subtle spectral differences such as particle size or concentration of a particular analyte, even if it is the same API or excipient. It is a very useful function to identify anomalies in the raw material or to perform a confirmation of the identification analysis in problematic or doubtful cases.

In all of the above cases, in addition to the result, the spectrum of the analysed substance is obtained for each measurement (Figure 6).

Figure 5: Raw material analysis classification Figure 6: Spectrum of each measurement

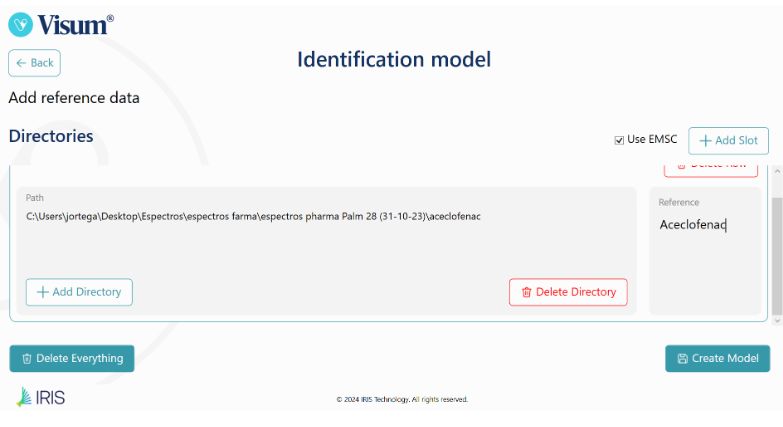

Develop your bespoke libraries with Visum Master™ software - Raw material analysis

Figure 7: Visum Master™ – Main Menu Figure 8: Visum Master™ – Develop from scratch a library or method for raw material analysis

Figure 9: Insert spectra and the reference to create the model.

The Visum Palm GxP™ is the only NIR analyzer on the market that allows end users to easily and automatically develop their own libraries for identification, classification, or even quantitative testing methods—all without requiring complex software or advanced knowledge of chemometrics.

Users simply need to import the training sample spectra and their reference values (quantitative or qualitative, as provided by the official method) into the built-in Model Builder. The software will then automatically generate the library or method, along with a technical report that includes details on the model’s construction and key performance metrics.

This report follows the criteria and recommendations outlined in ICH Q2(R2) “Validation of Analytical Procedures – Scientific Guideline”, making it suitable for internal and external validation, and helpful for identifying potential improvements or updates.